Semi-circular Curved Flute Panel Cement Concrete Board

Semi-circular Curved Flute Panel Cement Concrete Board

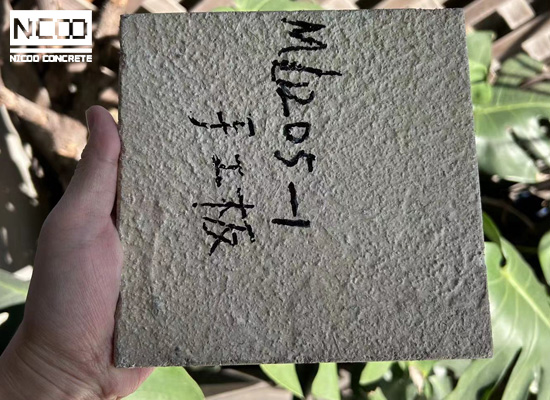

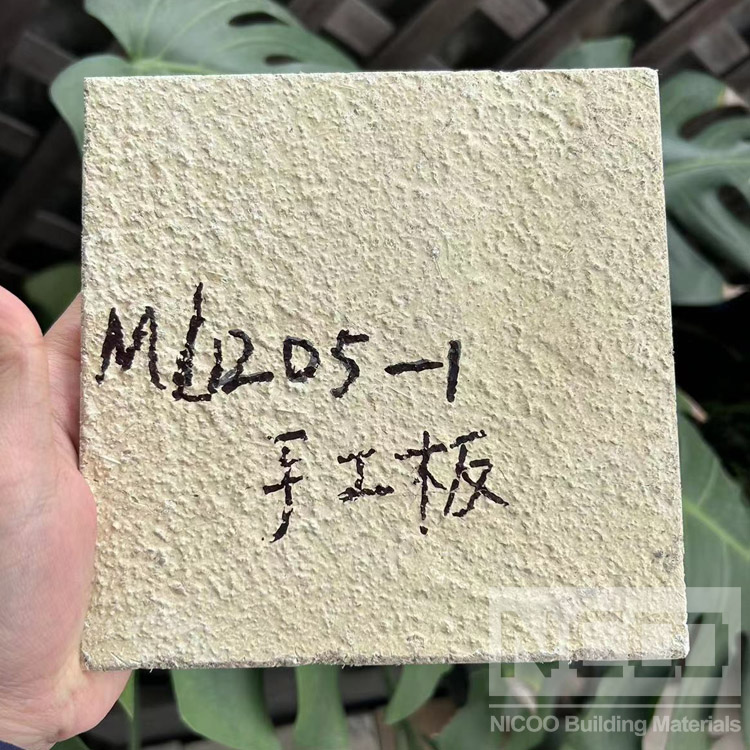

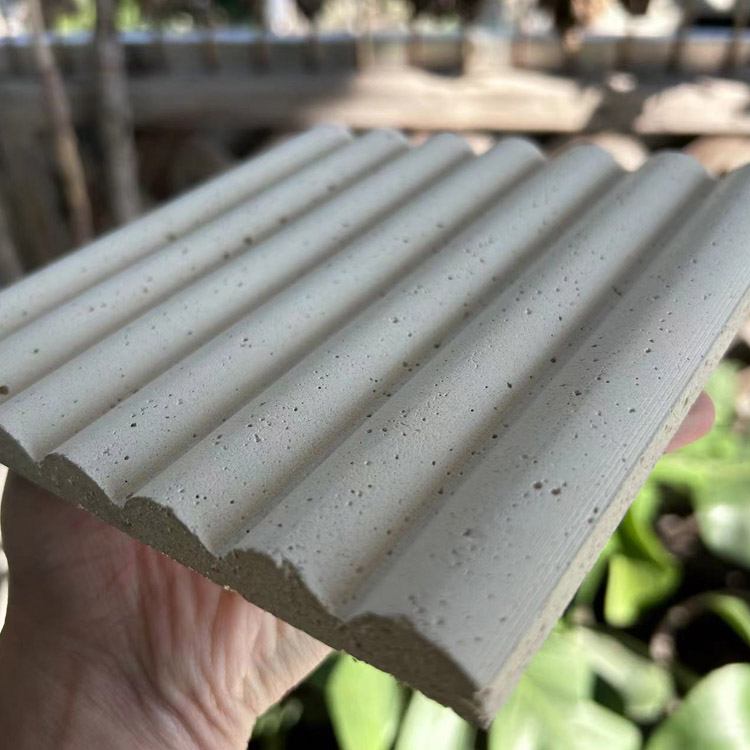

The Cement Concrete Board, with its vertically aligned facade and rough semicircular grooves in the middle, creates a stunning character to the wall decoration. The concrete slab has a small perforated surface and the size of the holes can be adjusted to suit the decorative style of each designer. By the way, the color of this sample is light yellow, because the color taken under different lighting and equipment may be different, we can provide color cards and free samples to customers, please feel free to consult our latest products.

Product Show

The Cement Concrete Board not only has delicate texture, but also has the general strength and stability of cement. When using, there is no need to consider the joint problem, which can create a continuous, flowing and integrated spatial vision.

Zero formaldehyde and zero VOC, is a green and healthy choice for the environment and human body.

Semi-circular Curved Flute Panel is our latest design style with fireproof grade, non-flammable, high safety, which is handmade by NICOO factory.

Lightweight and thin, when compared with natural stone, and with acoustic and thermal properties, NICOO Concrete's precast wall panels provide a unique solution to every vertical space.

A comparison of the effects with and without light. NICOO Concrete is aesthetically pleasing in both internal and external applications that will make your vision a reality.

Exterior Wall Installation

1. Precast cement board preparation: according to the size and design requirements, installing the supporting aluminum accessories(six aluminium accessories per sheet) on the back of cement board (maximum cross section size is 2780 * 1220 mm). Making cross line according to the vertical distance ( 600 mm ) between the transverse keels and length of cement board uniform size, then fixing supporting aluminum fasteners at the intersection,using 10 mm long and 4 mm thick stainless steel screws.

2. Construction wall preparation: cleaning up the wall surface, and then marking out the position lines and partition lines of the steels according to the design drawings and actual needs.

3. Wire hanging: vertical wire hanging should use the Φ1.0-Φ1.2 size steel wire, with 8-10 kgs weight lower counterweight iron, and the upper end is hung on the special wire hanging Angle iron frame. The angle iron frames are fixed on the top corners of the wall with expansion bolts, and marking on the top and bottom of the control line.

4. Keel installation: first fixing 50×50×4 angle iron (with adjustable hole) on the structural surface with 8 expansion bolt,that horizontal distance between the angle iron and the 50×50×3.5 vertical square steel tube on the angle steel is 800mm. When installing the vertical square steel tube, it must be checked by hanging steel wire from top to bottom to detect its Perpendicularity. After that, installing the fastening angle iron and the transverse aluminum keel (with 600mm spacing). The connection between angle iron, square steel tube and transverse keel is made with Φ10 bolts. Last, using the infrared level meter to detect whether the horizontal aluminum keel is horizontal, and the steel line to detect whether it is vertical.

5. Cement board installation: mounting the advance processing board on the keel according to the design drawings, and using aluminum accessories to connect the panel and keel. Hanging lightly the same level layer cement boards on the keel.

Package

Standard exportable carton box with/without wooden pallet, according to customers' demand.

FAQ

When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality.

If you just need a sample to check the design and quality, we will provide you sample for free.

What is your terms of delivery?

We accept EXW, FOB, CFR, CIF. You can choose the one which is the most convenient or cost effective for you.

Why choose us?

1. Owner of manufacturer and Export all over the world.

2. Each mouth we will recommend our new arrival to you specially.

3. Delivery in Time

4. Perfect workmanship and Customer first

5. High quality with reasonable price

6. Quick response to all your inquiry

7. Offer complete product line of items you could think of, It means total solution for your project.

Welcome to visit us to view more details.

Mosaic Terrazzo Application Advantages

Mosaic terrazzo is a kind of beautiful and practical material, which can be widely used in retail stores and various decoration projects.

FAQS About Flexible Tiles

What's flexible tiles?

The Three Indicators of Concrete Include

As a commonly used building material circulating in the construction industry today, it is common to hear about the three main indicators of concrete to meet design requirements. So, what are the three main indicators of concrete?

Artificial Traverstone Exterior Wall Case, Designers Look Over!!

Traverstone, a kind of natural stone, with its unique texture and beauty, shows a different charm on the exterior wall of the building.