About Terrazzo

About Terrazzo

Terrazzo (also known as whetstone) is a product made by mixing aggregates such as crushed stone, glass, quartz stone into cement binders to make concrete products, and then grinding and polishing the surface. Terrazzo made of cement binder is called inorganic grindstone, and terrazzo made of epoxy binder is also called epoxy grindstone or organic grindstone.

Terrazzo has a huge market in the world due to its unique advantages such as unique shape, high quality, attractive price, arbitrary color matching and parquet, and convenient construction. The terrazzo floor has been used in various urban and rural buildings around the world. There are as many as one billion square meters.

▲Colored stones for terrazzo (multicolored stones, stone rice)

Terrazzo Features

Terrazzo artificial stone has both the natural texture and firm texture of marble, the smoothness and delicacy of ceramics, and the ease of processing and richness of patterns. As a renewable material, endless creativity can be exerted in a limited space.

The characteristics of terrazzo material are outstanding in all aspects, such as: non-toxic, non-radioactive, flame retardant, non-stick oil, non-permeable, anti-bacterial and mildew-proof, wear-resistant, impact-resistant, easy to maintain, seamless splicing, versatile and so on.

Its characteristics are embodied in the following five points:

(1) After the high-grade terrazzo (also known as commercial terrazzo) is treated with high brightness, the high brightness reaches 70~90 degrees or more, and the dust-proof and skid-proof reaches the marble quality.

(2) Wear-resistant terrazzo and surface hardness can reach 6-8 grades.

(3) Existing or prefabricated terrazzo, which can be spliced at will, and colors can be customized.

(4) The new type of terrazzo does not crack, is not afraid of being rolled by heavy vehicles, is not afraid of being dragged by heavy objects, and does not shrink and deform.

(5) No dust, high cleanliness; cleanliness meets the requirements of high clean environments such as pharmaceuticals and chip manufacturing.

(6) Inorganic terrazzo is non-combustible, non-flammable, anti-aging, anti-fouling, anti-corrosion, no odor and no pollution.

(7) The color is bright and clean. If you need to improve the brightness, use floor wax or crystallization (without affecting its anti-static performance), harden and wear-resistant terrazzo, and maintain long-term beauty without waxing.

(8) The existing terrazzo decorative grids are horizontal and vertical, and there is no need for gaps between the grids, the connection is dense, and the overall aesthetics is good; commercial terrazzo can be arbitrarily designed with patterns to achieve beautiful decorative effects.

▲The variety of terrazzo

Mechanical Properties

(1) Gloss: 60~95;

(2) Compression resistance (N/cm2): ﹥2744;

(3) Bending resistance (N/cm2): ﹥490;

(4) Strength: greater than 75~100#;

(5) Wear resistance: when 500g is greater than 8000 rpm, there is no obvious wear;

(6) Dust generation: <1mg/cm2.

Terrazzo Classification

Terrazzo is divided into on-site pouring terrazzo and prefabricated terrazzo floor according to the construction and production process.

Cast-in-place Terrazzo

Pure terrazzo must be poured on site, commonly known as in-situ terrazzo. Simply put, it is to mix natural crushed stone, glass, even some precious gems, jade seeds and other aggregates and pigments into cement, and then polish and polish after setting. The formed cement products require on-site construction, can be arbitrarily parquet, can be dyed into various colors with pigments, and use glass or copper strips as partitions, with good decorative effects.

▲Cast-in-place terrazzo, currently mainly used for tooling in China, and rarely used for home decoration

Precast Terrazzo / Epoxy Resin Terrazzo

The precast terrazzo is uniformly produced by the production machine in the factory production line. The precast terrazzo slabs can be directly paved when needed. The gloss is higher than that of the terrazzo constructed on site, but the decorativeness is not as good as that of the terrazzo constructed on site.

Due to the limitations of pouring terrazzo on site, terrazzo tiles are a good substitute. There are two options for terrazzo tiles: terrazzo tiles and imitation terrazzo tiles. Terrazzo tiles are terrazzo that has been poured and cut in advance. The construction is simple and the texture is good.

Terrazzo floor is used in villas, hospitals, squares, subway stations and other grounds. It is more ornamental and classier than industrial terrazzo. Green and red marble stones, high-grade white cement or colored cement are generally used. , dust-free and wear-resistant, easy to clean, the same effect as marble.

▲Innovative Terrazzo Solutions

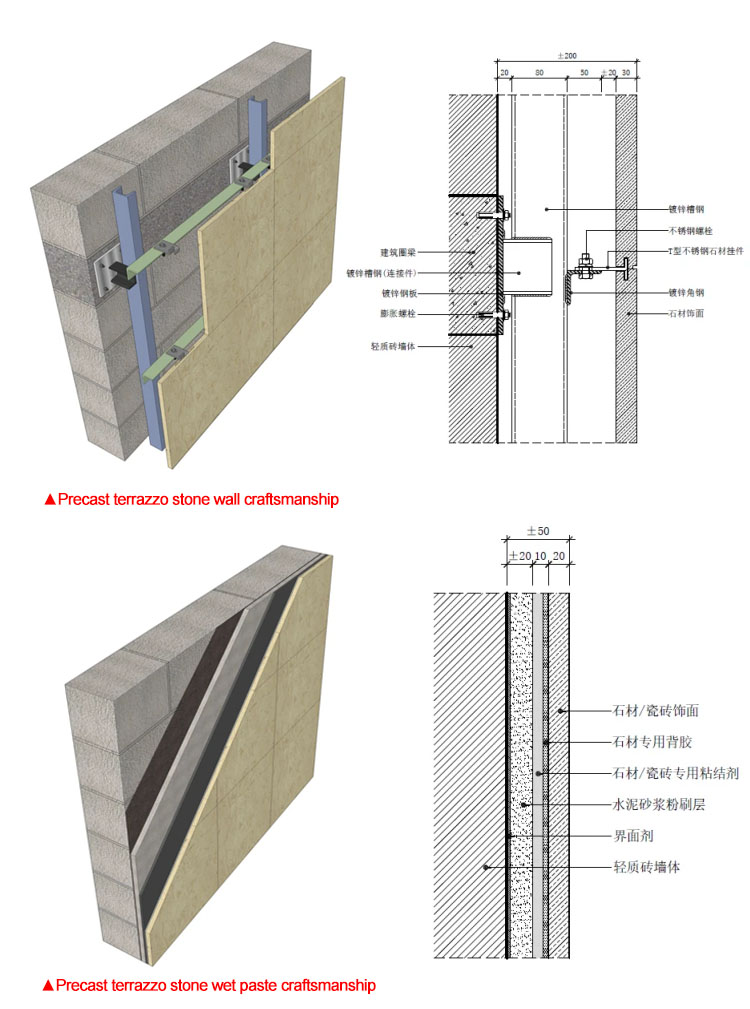

Precast Terrazzo Stone Wall Craftsmanship

We can understand precast terrazzo tiles as natural stone or ceramic tiles. Because from the point of view of the craftsmanship of the wall, in fact, the difference is not big. Mainly use dry hanging and wet sticking. Just after it's finished, it will do a whole polishing process. Therefore, the way of terrazzo on the wall can be realized by referring to the dry hanging of the stone.

The thickness specifications of terrazzo prefabricated sheets are divided into: 15mm, 20mm, 30mm. We only need to reserve the minimum finished surface thickness of 80mm, and the other nodes are exactly the same as the dry hanging of the stone.

Precast Terrazzo Stone Wet Paste Craftsmanship

As mentioned earlier, precast terrazzo can be understood as natural stone, and can be dry hung at the same time, so precast terrazzo can also be installed on the wall by wet sticking.

However, compared with natural stone, there are fewer terrazzo on the wall, so there is less stone that is wet pasted on the wall.

Therefore, for the practice of wet sticking terrazzo to the wall, you can also refer to the standard wall wet sticking process.

How to Choose A Good Rammed Earth Board?

The rammed earth board is prefabricated in the factory, and it can be directly mounted on the site. Designers who like everything can be prefabricated should come over.

60 Questions about Concrete Projects - Part 4

The most comprehensive questions and answers about concrete are here. If you want to know more or want to buy decorative plate can contact Nicoo directly.

How to Identify the Quality of Flexible Stone

China professional manufacturer NICOO teaches you to identify the quality of flexible stone.

The Application of Liquid Marble

Learn about 3D art marble. With the development of science and the progress of technology, stone processing technology is diverse, stone crafts have broken through our inherent imagination. You do not expect that the hard natural marble has become so soft and romantic.