Key Points of Production and Installation of Fair-faced Concrete Slabs

Key Points of Production and Installation of Fair-faced Concrete Slabs

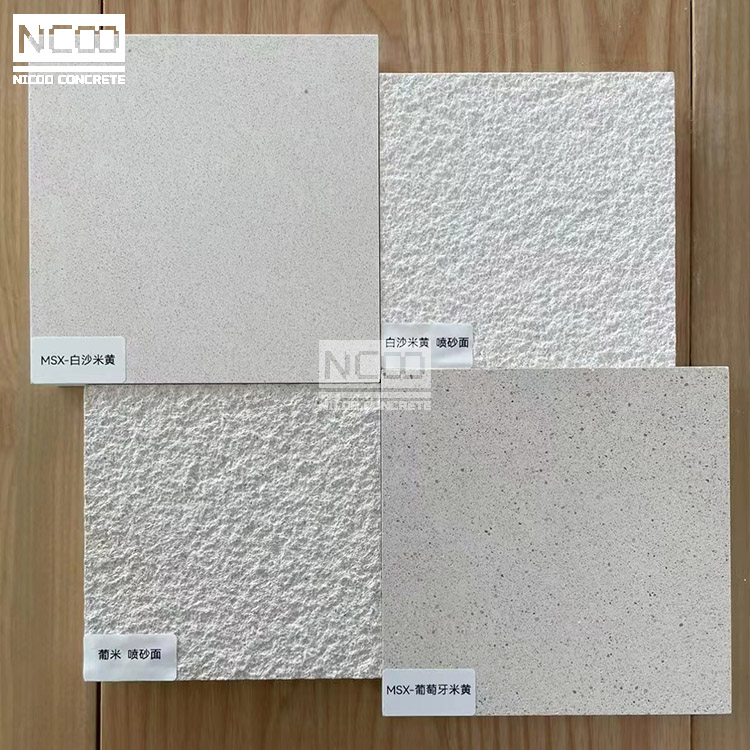

In the process of making the fair-faced concrete slabs, there are some key points. Today, the editor of NICOO Concrete will briefly summarize one or two, hoping to help you.

1. Production points

The formwork keel should not have joints. If the joint method is really necessary, the number of joints in the same section should not exceed 50%; the size of the blanking of the formwork parts should be accurate, and the incision should be flat; the panels, ribs, back corrugations and other components should be leveled before assembling Straight, it should meet the requirements of strength and stiffness; the material of the wooden formwork should be dry, and the incision should be planed; the formwork should be pre-assembled after processing, and the surface flatness of the formwork, section size, yin and yang angles, the height difference between adjacent boards, and the tension The bolt combination is checked, and the template is numbered according to the pre-assembly.

2. Main points of formwork installation

1) Before installing the formwork, check the cleanliness of the panel, check the model and quantity of the formwork and accessories, check the position of the open seam, cicada seam, and decorative pattern, check the attachment of the inner side of the formwork; check the control line and elevation of the internal and external formwork on the base. The release agent should be applied evenly. The formwork panel is not clean or the release agent is sprayed unevenly, which will affect the finish of fair-faced concrete. The template that has been brushed with the release agent should be re-brushed when it is exposed to rain, water or the release agent fails. Finished fair-faced concrete and decorative fair-faced panels whose quality acceptance standards are not lower than those of veneered fair-faced concrete shall not have traces of ink lines, oil stains, rust, etc.

2) Formwork installation should have anti-leakage measures. Leak-proof slurry measures can be taken by sticking sponge strips on the side of the formwork. After the sponge strips are squeezed tightly, they should not protrude from the board surface; the gap at the lower part of the vertical formwork should be tightly sealed.

3) The formwork panels, corners and fair-faced concrete surfaces should be protected. During the construction of the formwork, the formwork is easy to be scratched with the steel bar, the surface of the fair-faced concrete, etc., causing the formwork panel to be damaged and affecting the finishing effect of the fair-faced concrete.

Carpets, wooden squares or multi-layer boards can be isolated from steel bars, and measures such as pulling into molds can be used.

4) Assemble the template according to the number on the template. The connection between the templates should be tight and easy to dismantle.

5) When installing the tie bolts, the position should be correct, the force should be uniform, and there should be measures to prevent slurry leakage. Incorrect installation of the pull bolts will easily cause damage to the formwork and leakage of slurry at the hole through the wall. During installation, adjust the position and gently place it in place to ensure that each hole has a plastic washer to avoid thread damage to the formwork panel. hole through the wall. When tightening the connecting parts such as the tie bolts and formwork fixtures, the force should be uniform to ensure that the plastic washers are in correct contact with the formwork plate surface, and to avoid irregular deformation of the holes after the concrete is poured.

UHPC Performance Upgrade and Industry Application

Ultra-High Performance Concrete, referred to as UHPC (Ultra-High Performance Concrete), also known as Reactive Powder Concrete (RPC, Reactive Powder Concrete), is the most innovative cement-based engineering material in the past three decades, achieving a great leap in the performance of engineering materials.

Why choose inorganic travertine?

New building material prefabricated inorganic traverteite plate.NICOO can provide free samples, so that customers more intuitive to see the quality of traverite plate.

The Three Indicators of Concrete Include

As a commonly used building material circulating in the construction industry today, it is common to hear about the three main indicators of concrete to meet design requirements. So, what are the three main indicators of concrete?

Designers must understand the difference between terrazzo and terrazzo tiles

Terrazzo is divided into three types : 1. Cast-in-place terrazzo 2. Terrazzo prefabricated board 3. Terrazzo tiles