60 Questions about Concrete Projects - Part 4

60 Questions about Concrete Projects - Part 4

46. How should ready-mixed concrete enterprises prevent the phenomenon of insufficient supply?

Ready-mixed concrete production enterprises should be verified by the legal metrological department of the electronic scale of the mixing station every year, and the enterprise should also check the electronic scale of the mixing station once a month. The measurement error of sand and stone should be ≤±3%, and the measurement error of admixture, cement, admixture and water should be ≤±2%. If beyond the above requirements, to stop production in time to find reasons to solve.

47. What technical issues should salesmen pay attention to when signing contracts?

Ground engineering to understand the length and width of its dimensions, where the length of more than 30M to inform the technical department in time, to prevent the ground from irregular cracks.

The ground engineering should know whether the upper part of it has a finishing layer, whether it is the light ground with the pressure (that is, the surface will not do any decoration after the ground pressure), such as the light ground with the pressure must be noted, and the price should be increased appropriately.

48. What should we pay attention to when signing contracts for group projects?

There are dozens or even dozens of projects in a park. When signing the contract, the name of each individual project should be indicated, and payment collection should be controlled according to the contract respectively. Otherwise, the final payment will be paid until all the concrete bodies are completed during the construction of the group project.

49. What is the difference between the completion of the concrete main structure, the completion of the project main structure and the completion of the project?

The main structure of the project includes concrete structure, masonry structure, steel structure, etc., and the completion of the whole project includes the main structure, waterproof, plastering, plumbing, electrical, decoration, doors and Windows and other projects. The quality of concrete is only related to the concrete structure in the main structure. Therefore, when the contract is signed, the balance of the project shall not be paid after the completion and acceptance of the main structure project or the whole project.

50. What should we pay attention to when settling the project drawing on the ground?

Before the completion of the underground works and the commencement of the above-ground works, the pouring of the underground works shall be checked and confirmed by both parties.

51. What should we pay attention to before the project starts?

Before the project starts, the director of the production and technical department shall personally go to the site to understand the situation of the road and the ground of the factory, whether there is backfill soil and high voltage lines, whether there is a ban on trucks in the area where the project is located, determine the working position of the pump truck and the driving route of the tank truck, and formulate safe construction measures to prevent the backfill land surface from causing accidents such as car crash, overturning and high voltage electric shock.

52. What should we pay attention to in the process of contract implementation?

After the implementation of the contract, special personnel should be sent to the site to check the concrete supply, and the settlement statement should be issued regularly. When the concrete supply is close to the contract settlement amount, the user should be notified in advance to prepare the payment for goods, so as to prevent the oversupply and overstock of the payment, resulting in the low return rate of ready-mixed concrete enterprises and difficulties in operation.

53. Why does the contract require the user to fill out the concrete production order form before each pouring?

All the management of the enterprise should be recorded in written form. Although the user has notified the ready-mixed concrete enterprise by telephone 24 hours before the concrete is needed, the notice of the gate is often wrong, especially the concrete model is often miscommunicated, misheard and misrecorded, resulting in engineering accidents. Therefore, the concrete production order must be filled out by the user personally, including pouring site, model, quantity, technical requirements, pouring time and other information.

54. What are the advantages and disadvantages of reinforced concrete structures?

Advantages: reasonable use of materials; Good modulability; Good durability and fire resistance, low maintenance cost; The integrity of cast-in-place concrete structure is good, and through appropriate reinforcement, it can obtain good ductility, vibration resistance and radiation resistance. Large stiffness and damping are beneficial to the deformation control of the structure. Easy to use local materials.

Disadvantages: since heavy; Poor crack resistance; Limited bearing capacity; The construction is complex, many processes (supporting mold, binding reinforcement, casting, maintenance, etc.), the construction period is long, and the construction is greatly affected by the seasons and weather; e) Once the concrete structure is damaged, it is difficult to repair, reinforce and reinforce it.

55. What are the effects of concrete cracking on the structure?

①Cracking affects the integrity of the structure.

②Cracking can cause durability problems;

③Cracking causes loss of service function;

④Cracking is aesthetically unacceptable.

56. What are the main factors affecting the strength of concrete? How is it affected?

The main factors affecting the compressive strength of concrete are:

①Cement strength class and water cement ratio. The higher the cement strength grade, the higher the concrete strength; On the premise of ensuring dense forming, the lower the water-cement ratio, the higher the strength.

②Aggregate variety, particle size, gradation, impurities, etc. When the gravel and sand with larger particle size, better gradation and clean can reduce the water-cement ratio and improve the bond strength of the interface, so the strength of the concrete is high.

③Curing temperature and humidity. The influence of temperature and humidity on the strength of concrete is realized by influencing the hydration setting and hardening of cement. When the temperature is suitable and the humidity is high, the strength develops quickly, otherwise, it is not conducive to the growth of concrete strength.

④The longer the curing time, the more thorough the hydration, the smaller the porosity and the higher the strength of the concrete.

⑤The construction method mainly refers to the mixing and vibrating forming process. The strength of concrete is higher when the mechanical mixing and vibration compaction are strong.

57. What are the effects of sand, clay, silt, fine debris and other powdery impurities on the properties of concrete?

The content of clay, silt and fine debris in sand and stone increases. In order to ensure the fluidity of the mix, the water consumption (W) of concrete mixing will increase, that is, the W/C will increase. The powder materials such as clay will also reduce the interface bond strength between cement and sand and stone, resulting in the reduction of the strength and durability of concrete and the increase of deformation. If the strength is not reduced, the amount of cement must be increased, but this will cause the deformation of the concrete to increase.

58. What basic requirements should be considered when preparing concrete?

The following four basic requirements should be considered in the preparation of concrete, namely:

①Meet the strength grade requirements of structural design;

②To meet the requirements of concrete construction workability;

③To meet the engineering environment of concrete durability requirements;

④In line with economic principles, that is, save cement to reduce the cost of concrete.

59. The harm of adding water to concrete quality is analyzed theoretically.

When pouring concrete on site, the construction personnel add water to the concrete mix. Although the water consumption is increased and the fluidity is improved, the cohesiveness and water retention of the concrete mix are reduced. In particular, the increase of water-cement ratio W/C increases the content of pores inside concrete, which will reduce the strength and durability of concrete, and increase the deformation of concrete, resulting in quality accidents. Therefore, when pouring concrete on site, the construction personnel must be strictly prohibited to add water to the concrete mix at will.

60. What information should be provided by the customer?

The construction unit shall provide the structural construction drawings (beams, plates, columns, stairs, walls, etc.); Construction drawings (including construction columns, girders, lints, awnings, trenches, drainage slopes, bay Windows, cushion, ground, roof protection, level layer and balcony, modeling and other construction drawings), in addition to the construction process of change or drawing.

So all 60 questions about concrete have been answered.

If you have other questions about concrete or any other building material, contact NICOO.

Why choose inorganic travertine?

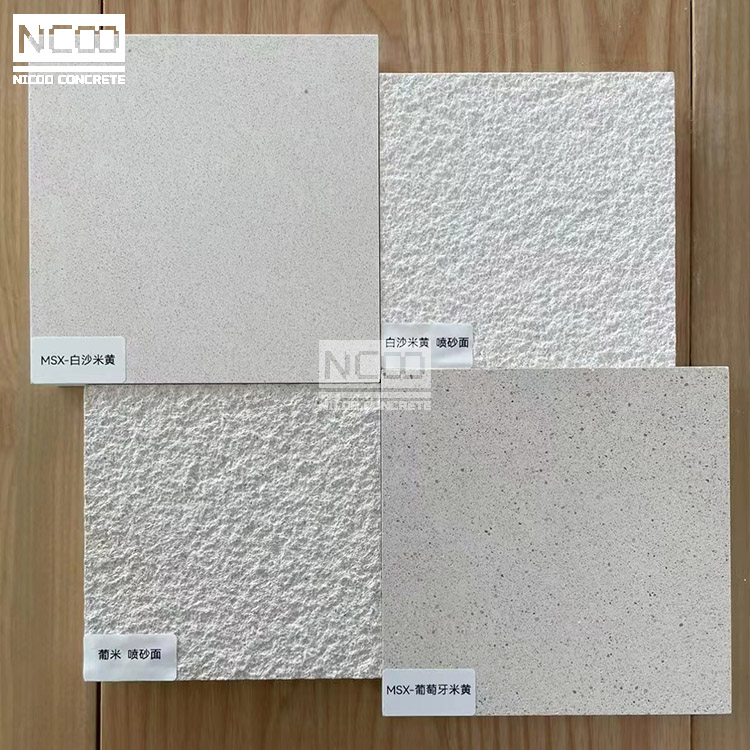

New building material prefabricated inorganic traverteite plate.NICOO can provide free samples, so that customers more intuitive to see the quality of traverite plate.

What is Rammed Earth Board?

First of all, correctly distinguish rammed earth board texture and rammed earth wall coating texture.

Application of Concrete in Modern Garden Landscape

In the garden landscape, fair-faced concrete can have more play space, different shapes and different decorative effects. As long as you can imagine, concrete can realize it for you.

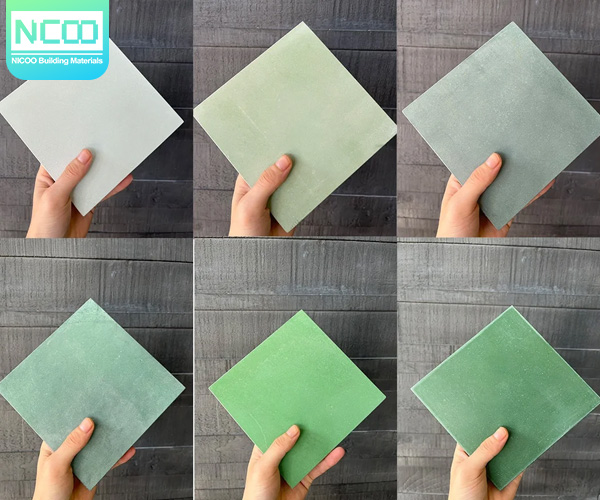

Hand-cast Fair-faced Concrete Slab Color Precast Cement Board

Who says fair-faced concrete slabs can only be drab gray? Today, I reveal to you a stunning treasure - colored concrete slab! It is not only a simple building material, but also a bright color in home design and garden landscape.