What is Rammed Earth Board?

What is rammed earth board?

As we all know, rammed earth has a long history. Its rough and original gravel texture makes people seem to smell the atmosphere of the earth, but the stability of the soil is not strong, and it is easy to break, not bending, seismic performance is not high and gradually fades out of everyone's vision. However, in recent years, a new material can perfectly replace it, to achieve its performance and performance enhancement, it is rammed earth board. So, let's talk about how do you use rammed earth? Mainly solve the following problems:

1. What is rammed earth board? What is the composition of rammed earth board?

2. What is the performance of rammed earth board? Construction technology, attention to the details?

3. What are the application ranges of rammed earth board?

First of all, correctly distinguish rammed earth board texture and rammed earth wall coating texture.

1. The difference between rammed earth plate and rammed earth wall

A. Rammed earth wall

Rammed earth walls are a kind of material in ancient architecture, used for building houses. It is made of clay, coarse sand and lime, which are mixed in a certain proportion and pressed into a solid, dense and less crevices. In addition, it is necessary to use a pestle to tamp the triad soil layer by layer, so as to remove the gaps in it, so as to truly become a rammed earth wall.

B. Rammed earth board

Rammed earth board is a kind of board whose texture is similar to rammed earth wall. As another technology form of rammed earth wall, it is the improved construction method of raw earth by adding lime and cement concrete to raw earth.

The installation is particularly convenient and fast, greatly shortening the construction period, and saving the cost. It is a kind of wall decoration plate with the same texture and rammed earth wall.

Good rammed earth board retains the natural gradual texture of modern rammed earth wall, reflecting the low-key, plain and simple properties of rammed earth wall incisively and vividly, and its thick and elegant texture is incomparable to other modern building materials. Moreover, the construction and installation are particularly convenient and fast, and the construction time is directly reduced by 80-90% compared with that of real rammed earth. Can meet some construction period is short, the budget is not too much of the project.

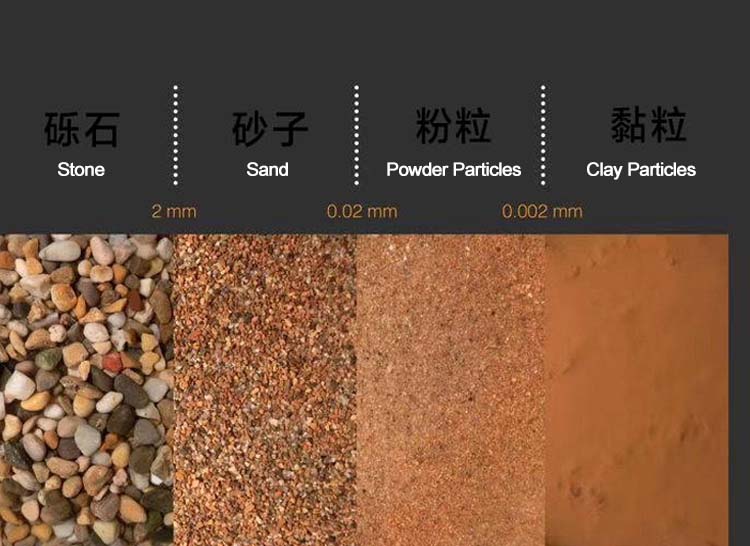

2. Composition of modern rammed earth board

Rammed earth board is made of clay, sand and stone, which are mixed together in a certain proportion to form aggregate similar to concrete. The aggregate is poured into the mold for curing and demudding process, so as to form rammed earth plate.

What are the properties of rammed earth plates?

As a new environmental protection material, rammed earth board has rammed earth texture, which is an innovative material attempt based on the pursuit of local texture and rock and soil texture. In the performance of the rammed earth wall is completely beyond the perfect solution to the original rammed earth wall in the use of defects.

A. Fireproof and waterproof performance

The fire rating of rammed earth board has reached the national fire protection and combustion performance level A, which can meet the requirements of high-rise buildings and various commercial Spaces. No water penetration, no fading, good waterproof performance, can be used for all kinds of space, including toilet.

B. The decoration performance is good, the material is close to nature

The natural rammed earth texture of rammed earth board, as well as its own thick and elegant texture are incomparable to other modern building materials. It can have a great impact both visually and spiritually, and convey the designer's creative emotions.

It can also create a modern high-quality rural life concept with natural life as the scenery and simple culture as the heart. It can be customized according to the project requirements to achieve the desired texture effect.

C. Ecological protection

Compared with the traditional solid brick, rammed earth plate does not need to be further processed, nor does it need to consume a lot of energy consumption, low cost, and, non-toxic and pollution-free, good environmental performance.

In addition, after the rammed earth panels are removed, they can be reused or returned to the land without generating excess construction waste.

D. Wide range of use

Rammed earth board is durable, UV resistance, aging resistance, acid, alkali, salt and wet areas have good corrosion resistance, not only can be applied to indoor, but also can be used for outdoor space.

E. Construction is convenient, fast, economic and durable

The construction process of rammed earth plate is simple, the installation is fast, and the construction time of real rammed earth is directly reduced by 80%~90%, which can greatly shorten the construction period. Local damage, just replace the plate, simple and rapid, convenient maintenance.

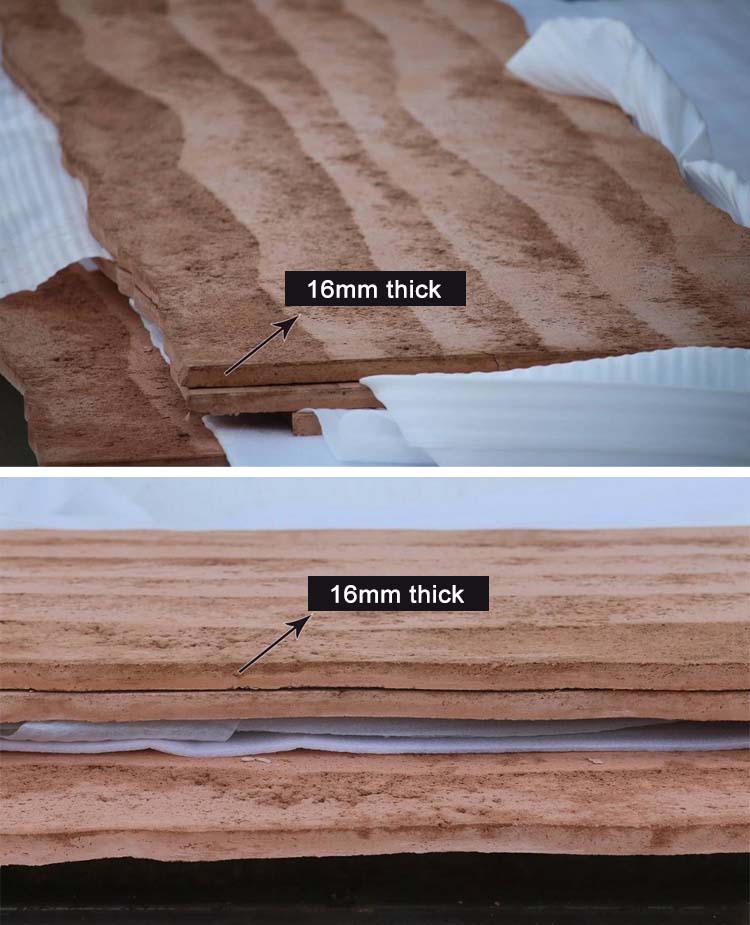

Specifications for rammed earth board

NICOO's regular specifications are: 3000*600*8mm/3000*600*16mm(this specification is a majority of rammed earth board), in addition, there are 1240*3250*3mm specifications on the market, if you need special specifications can also be customized according to demand.

The color of rammed earth board

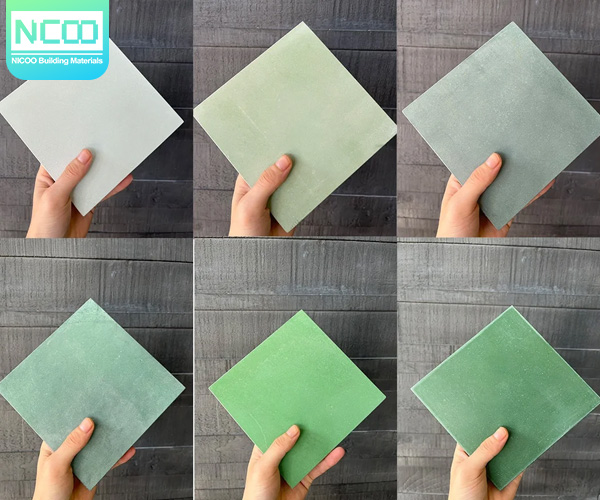

Common colors are red earth, loess and gray (colors can be customized according to the project effect)

How to construct rammed earth board?

1. Process of construction

The installation of rammed earth board is very convenient. The best installation scheme is straight row nail installation and structural adhesive installation. The external wall of the building adopts the form of dry hanging, and the landscape wall adopts the form of dry hanging or pasting.

A. Adhesive form

Process: basic leveling → bottom of the woodworking board → the reverse side of the rammed earth plate sizing, structural glue (nail free glue) from the edge of the rammed earth board 15cm, hit the spot shape, point spacing 10~15cm, paste → details processing → complete.

NOTE: The interior wall can not be made of gypsum board as the base, because the gypsum board surface has paper surface, resulting in the adhesion is not firm. During construction, it is necessary to ensure that the base surface and the sizing surface of rammed earth plate are dust free.

B. Dry hanging form

① Common dry hanging

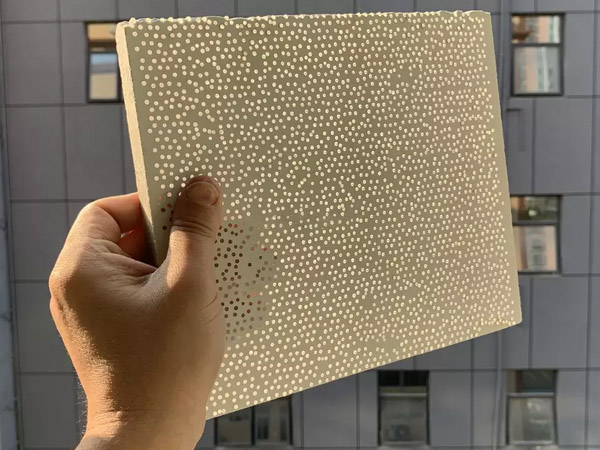

The keel of 2cm*4cm is fixed on the indoor foundation wall, and the spacing between the center of the wooden keel is 30cm. The rammed earth plate is arranged horizontally and fixed on the surface of the plate where there are many honeycomb holes with straight rows of nails.

② Reinforce the dry hanging

Apply a layer of liquid glue to the surface of the woodworking board. Lay the rammed earth board horizontally and fix it on the surface of the board where there are many honeycomb holes with straight rows of nails.

2. Construction notes

A. Surface gap treatment

The cracks on the surface need to be repaired with soil (mud) plastering, and the cracks need to be filled and repaired with thin slurry grouting and soil curing agent yellow mud plastering slurry.

B. Expansion joints are reserved on the board surface.

Because the rammed earth plate has certain characteristics of thermal expansion, cold shrinkage, wet expansion, dry shrinkage and elasticity, in order to preven.

Application range of rammed earth board

1. Applied indoors

As a new decorative material, rammed earth board is widely used in interior walls, ground, ceiling, furniture, etc. The natural and simple visual texture effect is perfectly integrated with other indoor materials. The unique texture of rammed earth board is used to enhance the texture of space.

2. Applied to architecture

The concept of environmental protection is strongly advocated all over the world, which, to some extent, also promotes rammed earth buildings to regain new vitality. Rammed earth board comes from its original ecological material, a low-cost environmental protection material that can be seen everywhere. When it is used in engineering construction, its impact on the environment can be minimized.

3. Applied to the landscape

The coarse and rustic rammed earth material perfectly combines with the outdoor environment and embraces the nature, presenting a thick and simple scenery wall effect.

More wonderful can send us information to get

Absolutely useful, precast concrete exterior wall panel design

Learn about precast concrete wall panel design you don't know about.

Wide Application of Inorganic Terrazzo

The beauty of inorganic terrazzo floor is not only reflected in the ground.

Introduction and Application of Light Transmitting Concrete

Light transmitting concrete or transparent concrete or translucent concrete is a concrete (made of rich raw materials, low cost and simple production)based material with light-trans missive properties, obtained by embedding optical fibres in it. Light is conducted through the fibre from one end to the other.

Hand-cast Fair-faced Concrete Slab Color Precast Cement Board

Who says fair-faced concrete slabs can only be drab gray? Today, I reveal to you a stunning treasure - colored concrete slab! It is not only a simple building material, but also a bright color in home design and garden landscape.