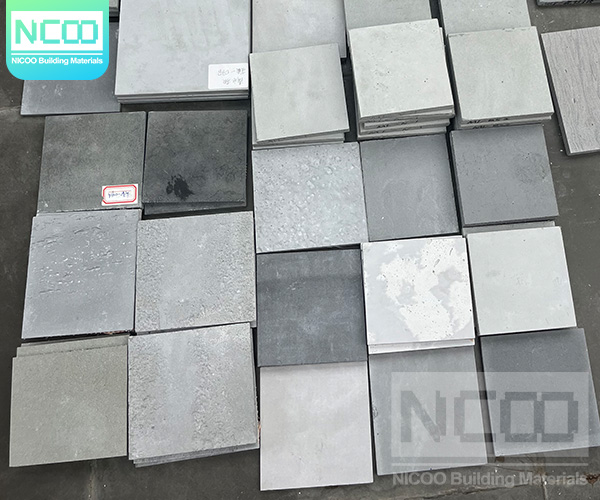

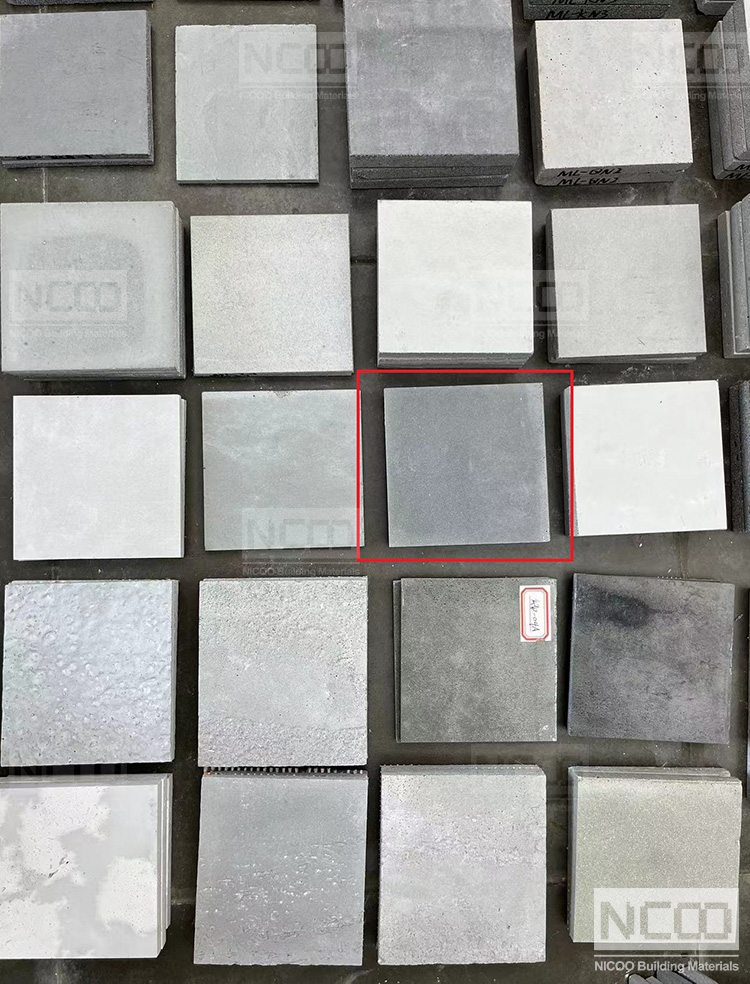

Vintage Grey Colour Concrete Slab Floor Exterior And Interior Precast Concrete Panel For Facade Cladding

The physical properties of cement determine its specific use. Composite Portland cement is a hydraulic cement material made of Portland cement clinker, 15% ~ 50% of two or more specified mixed materials, and an appropriate amount of gypsum grinding. Today, we will tell you about the use of precast portland concrete panel.

About Precast Concrete Panel

Our concrete wall panels are cast using a Composite Portland cement matrix, a high performance concrete that allows the panels to be made lighter, stronger, thinner and larger then conventional concrete. Our concrete wall panels are typically made at 10-25mm thick. Since there are no stone aggregates or metal reinforcing within a standard wall panel, NICOO concrete panel can be cut as easily as natural stone tile allowing you to order one generic size for efficiency or still design each wall panel to a custom size. Our regular size are including 600*1200mm,1000*1000mm,1200*1200mm and 1200*2400mm. With a custom concrete wall panel, designers do not need to be constrained by the limited size, shape, and color options of off the shelf or standardized products. Suitable for both exterior and interior uses, NICOO concrete wall panels act as a functional and aesthetic surface that will always last.

We provide free sample for each customer but freight, welcome to consult: leo@ltdisplays.com

About NICOO Precast Concrete Panel Feature

(1) High strength

Portland cement sets fast, high strength, especially the early strength growth rate is large, especially suitable for early strength requirements of high engineering, high-strength concrete structures and prestressed concrete projects.

(2) High hydration heat

The high content of C3S and C3A in Portland cement clinker makes the early heat release large, the heat release speed is fast, the early strength is high, and the construction in winter can often avoid freezing damage. However, the high heat release is unfavorable to the mass concrete project, if there is no reliable cooling measures, it is not suitable for the mass concrete project.

(3) Good frost resistance

Portland cement mix is not prone to bleeding, the hardened cement stone density is larger, so the frost resistance is better than other general purpose cement. It is suitable for concrete works subjected to repeated freeze-thaw action in cold areas.

(4) High alkalinity and strong carbonization resistance

The cement stone hardened by silicate cement shows strong alkalinity, and the steel bar buried in it generates a gray passivation film on the surface of the alkaline environment, which can keep the steel bar from rusting for decades. Portland cement has strong alkalinity, high compactness and strong carbonization resistance, so it is especially suitable for important reinforced concrete structures and prestressed concrete projects.

(5) Dry shrinkage

Portland cement in the hardening process, the formation of a large number of hydrated calcium silicate gel, so that cement stone dense, less free water, not easy to produce dry shrinkage cracks, can be used in dry environment of concrete engineering.

(6) Good wear resistance

Portland cement has high strength, good wear resistance, and dry shrinkage, which can be used for pavement and ground engineering.

(7) Low water yield

The clean water board is a fiber grid high-strength silicate cement board, and the high-pressure cement board is a fiber reinforced cement board, which is similar, but the latter has low strength, low weather resistance and high water collection rate

The composite Portland cement is between ordinary cement, pozzolanic cement, slag cement and fly ash cement. When the mixed material is less (less than 20%), its performance is similar to that of ordinary cement. With the increase of the mixed material, the performance also tends to the cement of the mixed material.

How to place the order?

Generally, we will manufacture this kind of precast concrete panel in batches. Our minimum order quantity is 50sq.m.. we have our own factory. Before that, we need to know the customer's requirements, such as quantity, size, thickness, style, color and other requirements, so as to make an accurate quotation. After the customer places an order, we will submit the detailed CAD drawings of the product to the factory. Our workers will strictly follow the content of the drawings to process. If you have requirements for the surface treatment, you can tell me at leo@ltdisplays.com or send us your information at the bottom of the website.

Raw stone - Inorganic artificial travertine stone

Artificial stone since its birth, after decades of development, has long been one of the mature decorative materials on the market, now more than 90% of the industry is resin artificial stone products, artificial stone is the future trend of inorganic artificial stone.

How to Install Rammed Earth Wall Panels

The construction process of the rammed earth board is simple and the installation is fast. The installation methods can choose straight row nailing and structural adhesive installation. The exterior wall of the building adopts the form of dry hanging, and the landscape wall adopts the form of dry hanging or mounting.

About New Eco-friendly Building Material Flexible Tile Stone

Flexible tile, also known as MCM tile, is a new type of environmentally friendly and recyclable building material, which is light and thin. Suitable for various architectural spaces

FAQ

FAQ about Nicoo Concrete