Color Precast Terrazzo Ceramic Tile Villa Floor Decoration Inorganic Green Terrazzo Slate

Color Precast Terrazzo Ceramic Tile Villa Floor Decoration Inorganic Green Terrazzo Slate

NICOO Terrazzo -- is originated from Italian formula, made of fragmental pebbles and different kinds of natural material mixed with cement. It is a fashionable, durable and environ- mental-friendly material with unique pattern after combination and polishing. NICOO Terrazzo is an inorganic terrazzo , no epoxy resin additions in the production process.

PRODUCT DESCRIPTION

| Brand Name | Nicoo |

| Model Number | Nicoo23725 |

| Item | Green color terrazzo tile |

| Place of Origin | Guangdong, China |

| Application | APARTMENT/HOSPITAL/OFFICE/BUILDING/LIVING ROOM/SCHOOL/MALL/SUPERMARKET/GARDEN |

| Style | Modern |

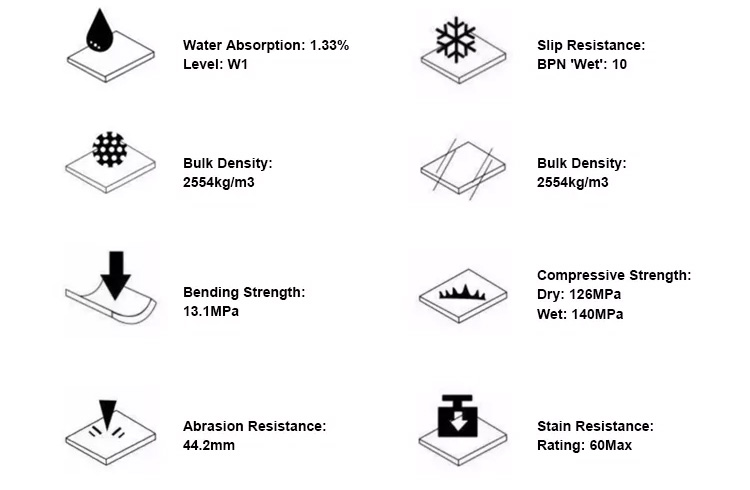

| Function | Non-slip, anti-slip, low water absorption |

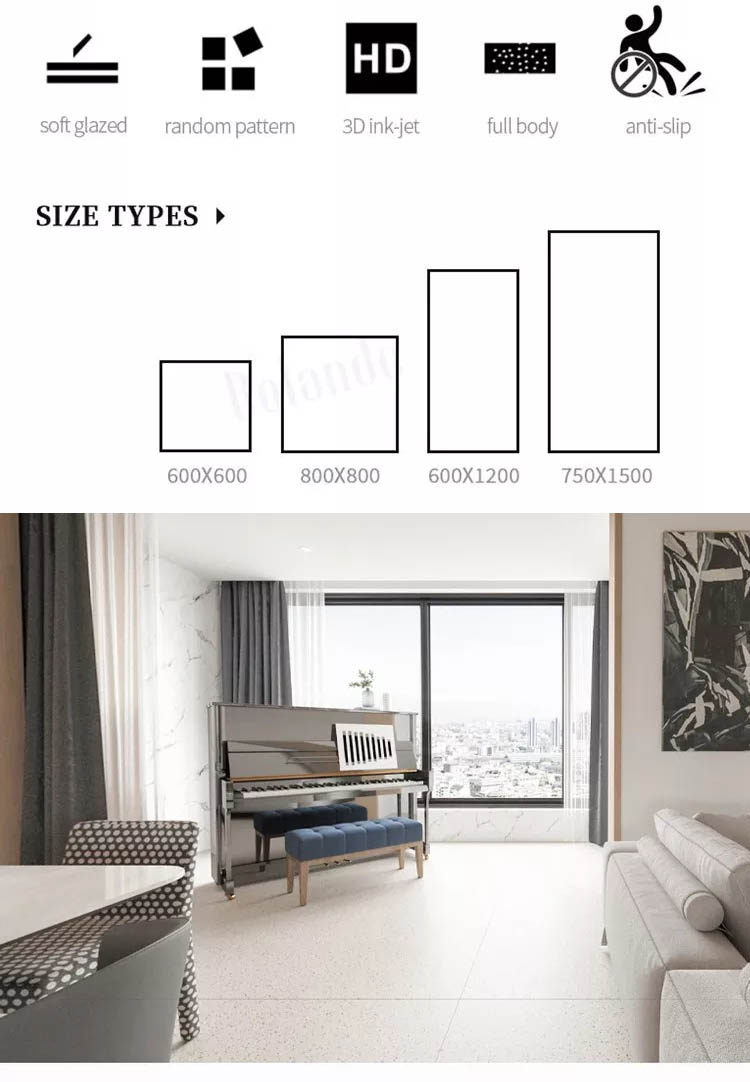

| Available Sizes | Slab: 2400up x 1200up x 15 / 20 / 30 mm |

| Tile: 305 x 305 x 10mm, 305 x 610 x 10mm, 610 x 610 x 10mm etc. | |

| Cut-to-size: 457 x 457 x 10mm, 300 x 300 x 20mm, 300 x 600 x 20mm, 600 x 600 x 20mm etc. | |

| Thickness | 2CM or Customized |

| Cut to size Surface finish | Flamed/Polished/Honed/Bush-hammered/Acid-washed/Leather |

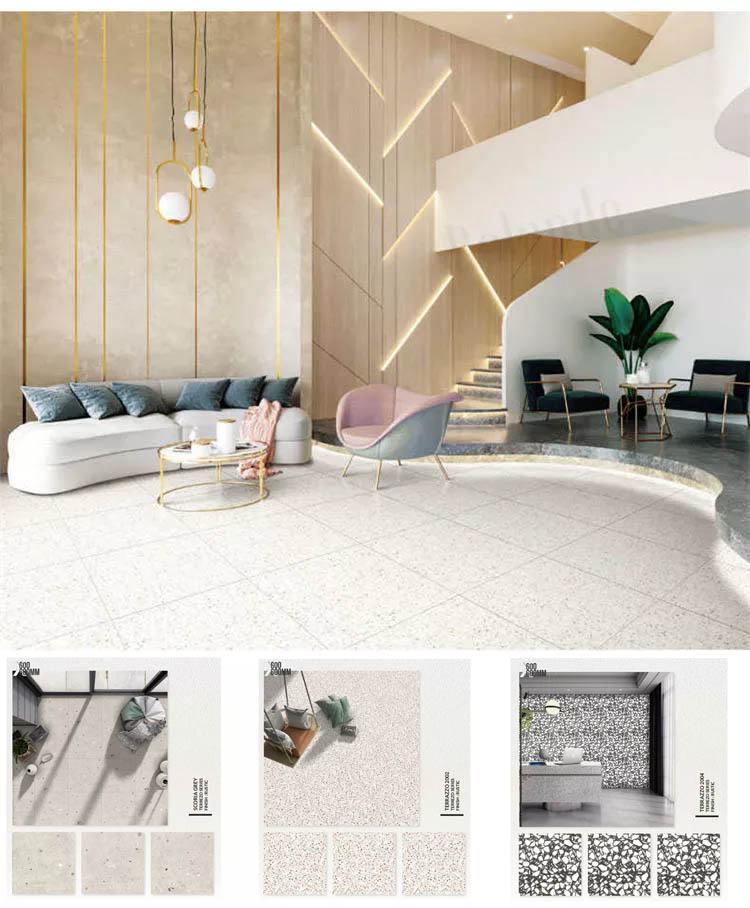

PRODUCT DISPLAY

PRODUCT ADVANTAGES

Rescource Regeneration : Exquisitely use waste stone scraps

Color Customization : Combine different stone color at will

Various Finish : Flamed , Bush-hammered , Acid-washed , Leather.

Cost Controlled : Excellent quality whith competitive price

Envionmental Safety : Resin-free , Anti-uv , No toxic fume

Particle design effect on the surface , matte non-slip.

High-quality imported glaze, delicate touch, pure and natural color, simpleand classic for indoor and outdoor.

Anti-slip and wear-resistant treatment

High melting point , hardness , anti-slip , wear-resistant and durable , and better anti-corrosion performance. The surface is processed with large and small particles, which is more realistic, and the product effect improves the design line texture and looks more classy .

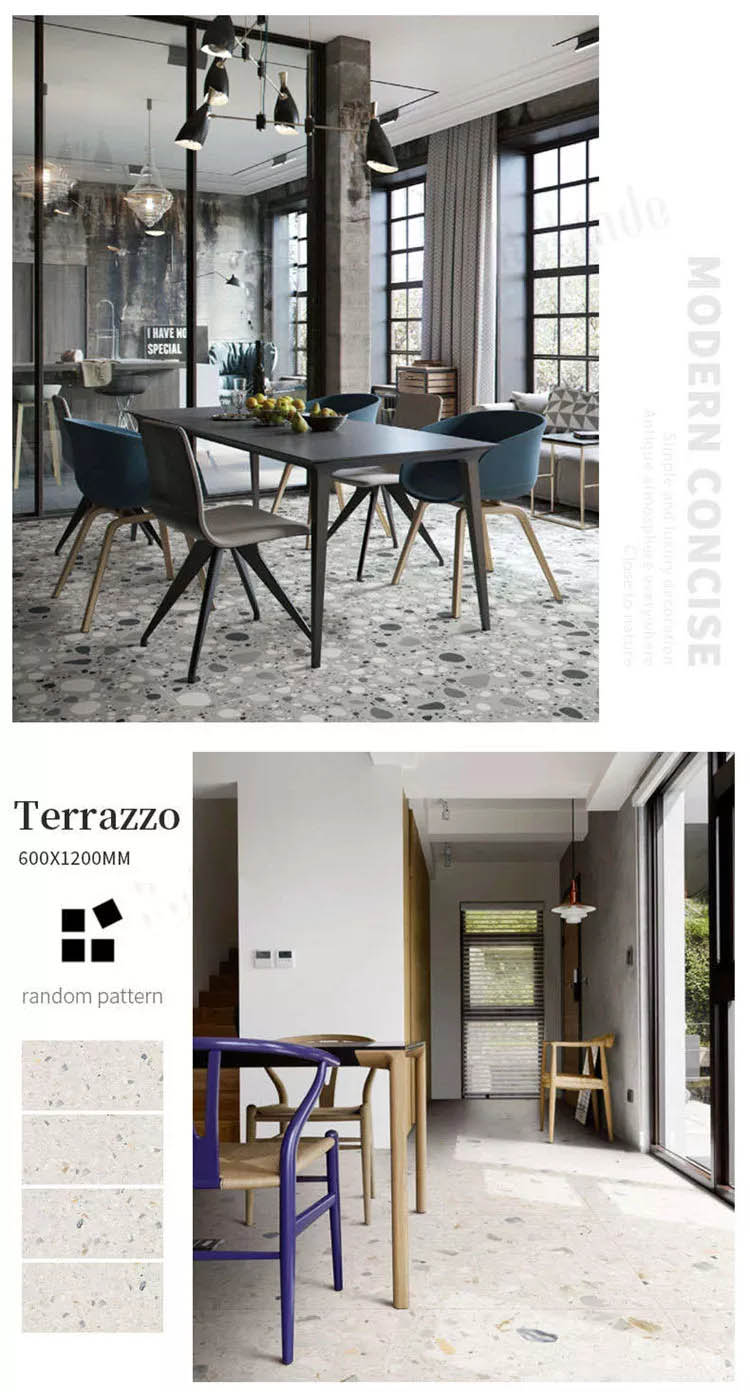

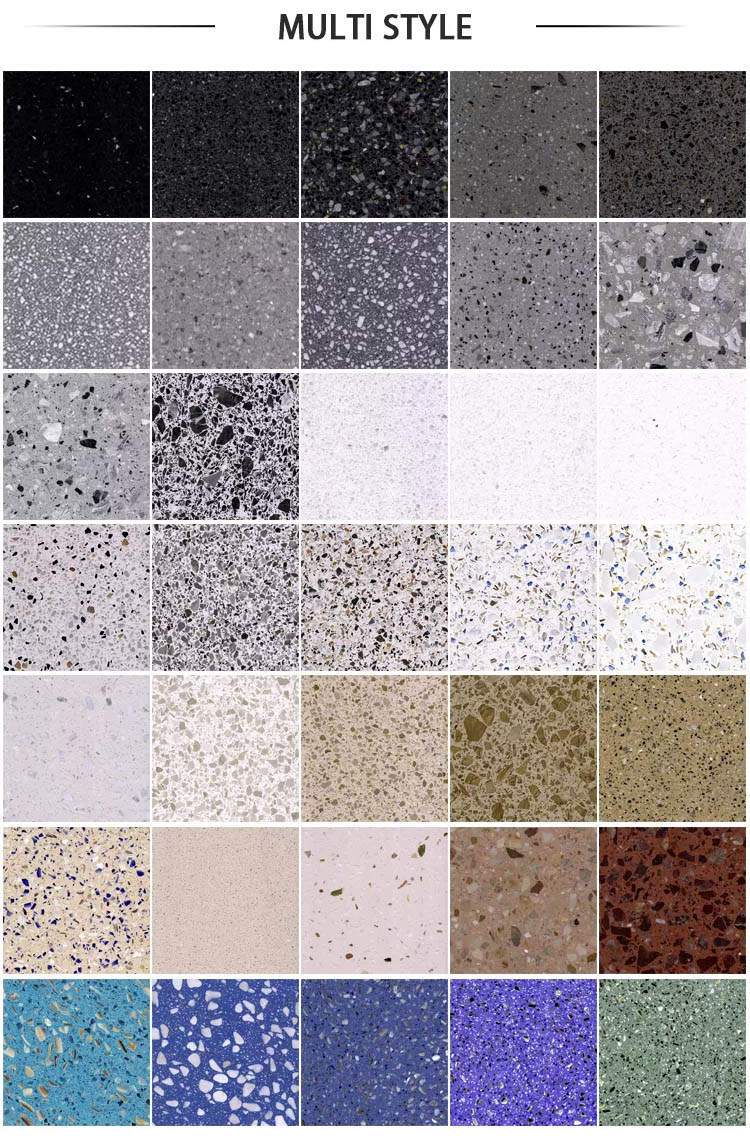

MULTI STYLE

Terrazzo comes in a countless variety of colors, designs and aggregate options that can mix with different styles.

Each terrazzo can be decomposed in the nature. We value the innovation as well as the development process of eco-friendly construction material, just to accomplish the goal of zero carbon emission. More products for your choose,please contact us>>

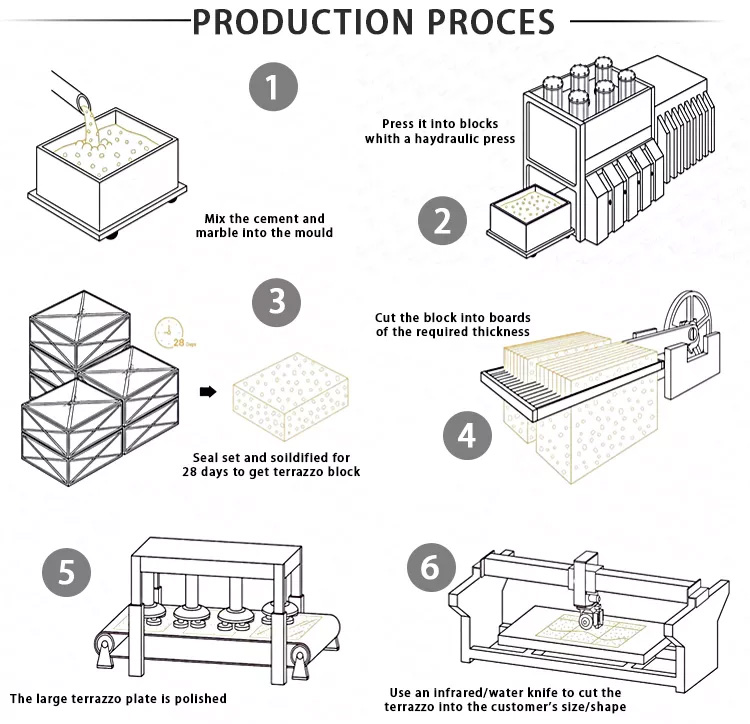

PRODUCTION PROCESS

① Mix the cement and marble into the mould.

② Press it into blocks whith a hydraulic press.

③ Seal set and solldlfled for 28 days to get terrazzo block.

④ Cut the block into boards of the required thickness.

⑤ The large terrazzo plate is polished.

⑥ Use an infrared / water knife to cut the terrazzo into the customer's size / shape

TERRAZZO PACKAGE

Packaging Details :

1) Tiles & cut to size in strong wooden crates. inside covers by foamed plastics (polystyrene).

2) Slabs in strong wooden bundle packing with L brackets of steel.

Port : Shenzhen, China

Supply Ability : 50000 Square Meter/Square Meters per Month

Flexible Tile Manufacturer Take You To Understand The Price

We know that the price of flexible tile from each manufacturer is different, how do we know whether the price he gives is expensive or cheap, let's take a look.

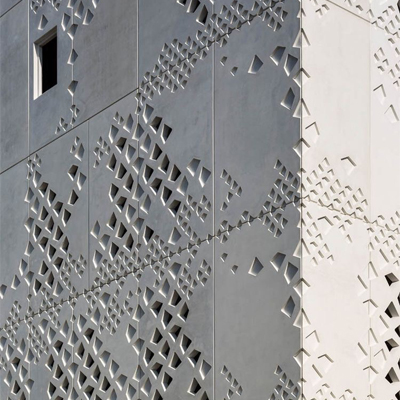

Can Inorganic Cave Stone Be Used In External Walls Instead of Stone?

Can inorganic holes replace the role of stone in the exterior walls? I'm sure we can. The walls are installed the same way. Both interior and exterior walls can be used, the specification is 1200*2400*25 mm.

2024 New Arrival Large Particle Terrazzo Tile Waterproof Precast Terrazzo Floor Panel Stone Tiles

Large particle terrazzo | can match the drawing of each board

UHPC Performance Upgrade and Industry Application

Ultra-High Performance Concrete, referred to as UHPC (Ultra-High Performance Concrete), also known as Reactive Powder Concrete (RPC, Reactive Powder Concrete), is the most innovative cement-based engineering material in the past three decades, achieving a great leap in the performance of engineering materials.