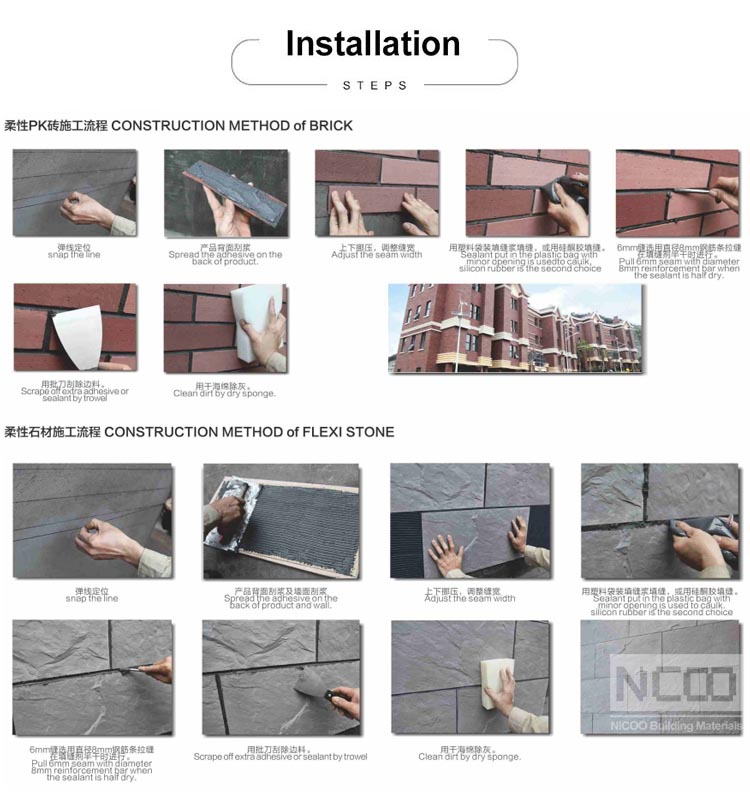

How to Install Flexible Tiles

Flexible tile exterior wall brick with its unique texture and thin characteristics in the building materials market gradually popular, but many customers do not know how to paste? Today flexible tile manufacturers to give you a detailed explanation!

1. The layout

According to the technical design requirements of the construction module test row, determine the width of the joint, grid test row can use the whole operation. Ensure the soft tile clearance is even, meet the design requirements. Pay attention to the large wall column and corresponding to the discharge of the whole brick, inevitably, the non-whole brick should be discharged in the window wall or shade corner and other minor parts, pay attention to coordination and symmetry. The soft tile around the wall protruded should be consistent with the whole brick set, the edge is neat, and should not be randomly pieced together with the non-whole brick. The size of flexible tile material is standard, vertical line and horizontal line pop up according to the effect of test row and multiples of the whole block.

2. The paste

①. Adhesive: flexible tile professional adhesive, stir evenly with power tools.

②. If the size of flexible tile or flexible brick is less than 300mm*300mm, the whole pulping method on the back of flexible tile can be used, and the thickness is 4mm. The specification is about 600mm*600mm. In the above case, the full pulping method of soft porcelain back and both sides of the wall must be used, and the thickness is about 3mm. Tooth scrapers should be used when scraping, and the depth of teeth should be 5~6mm.

③. Flexible tile paste order from top to bottom.

④. When pasting flexible tiles, use both hands to move back and forth knead and align, beat with plywood, so that the adhesive is evenly squeezed to the edge of the face brick, do not beat hard beat solid tiles with leather hammer or other objects.

⑤. When the flexible tile is pasted, the adhesive squeezed to the edge of the tile should be cleaned in time so as not to affect the joint effect.

⑥. Before the initial setting of the adhesive layer, the position of the surface brick and the width of the ash seam can be adjusted appropriately. After the initial setting of the adhesive layer to the complete solidification stage, it is strictly prohibited to interfere with the paste of soft ceramic tiles.

3. Seam Clearing / Caulking / Jointing

Non-dense joints shall be treated with a single component jointing agent (flexible tile specialty jointing agent with anti-alkali function, black or cement grey as determined by design) mixed in the same way as the adhesive.

①. Clear the seam: When stitching, because the thickness of soft porcelain itself is only 2~3mm, therefore, it is necessary to clean the seams to facilitate filling of seam agent slurry. If the joint is not cleaned, the adhesive at the joint cannot be dried for normal joint filling and joint operation. The joint cleaning operation must be completed before the initial setting of the adhesive. It is more convenient to clean immediately after pasting. You can use the spatula blade or small edge to replace the knife.

②. Caulking: After adjusting the caulking material, it can be poured into the plastic triangle bag, and the rear part is fastened;

According to the seam width requirements, cut a small mouth with scissors, squeeze out a bit, fill in the seam, appropriate seam. The caulk should not be too dry or too thin, so that the extrusion does not flow.

③. Jointing: After the caulk is properly collected, before drying (according to the weather conditions by the workers), with smooth steel bar jointing, should be from top to bottom, short seam after long seam. The diameter of the seam should be 2-4mm wider than the seam.

4. Clean

In flexible tile construction, whether in the bonding process or in the joint process, attention should be paid to try not to pollute the adhesive or joint filling material on the surface of the plate. If you accidentally touch the surface of the board, do not wet scratch the contaminated pulp before drying, because the scratch left will pollute the surface area of the board, which is not easy to clean up.

60 Questions about Concrete Projects - Part 4

The most comprehensive questions and answers about concrete are here. If you want to know more or want to buy decorative plate can contact Nicoo directly.

How to Make Curved Cement Boards / Shaped Precast Wall Panels ?

In many decoration projects, we often see that there are some curved walls, columns, or corner positions that need to install plates, so we need some special curved or shaped plates to match. So how do we produce these curved slabs of cement?

Unique Design 800*800 Potato Powder Large Particle Terrazzo

Puzzle style reinvention, custom design is a bit miscellaneous; Both have chosen to firmly take the customized route, this is today's production line master said the most warm words; Okay, so let's continue with the size effect... !

Absolutely useful, precast concrete exterior wall panel design

Learn about precast concrete wall panel design you don't know about.