What is colored concrete?

What is colored concrete?

Today is to introduce the colored concrete, colored concrete is one of the important members of the special concrete, is a kind of waterproof, anti-slip, anti-corrosion green ground decoration material, is in the wet cement floor plus a layer of colored concrete (decorative concrete), and then use a special mold in the cement floor pressed into.

Its characteristics are mainly reflected in the controllable change of concrete color, the selection of different colors to add to the charm of the main project, in addition, after years of research, application and improvement, gradually developed into a new type of decorative concrete, and widely used.

-01- Performance

Colored concrete can make the cement floor permanently show a variety of colors, patterns, texture, realistic simulation of natural materials and textures, at will to draw all kinds of patterns, and the longer the new.

1. Beautiful appearance, three-dimensional sense, rich pattern, color, do not fade, do not change color, and can be made according to the need of special patterns. 2, impact resistance, corrosion resistance, its service life is more than cement, up to 15 years.

2. Impact resistance, corrosion resistance, its service life is longer than cement, up to 15 years.

3. Non-toxic and harmless, although colored concrete with color, but it does no harm to the environment and human body.

4. Oil resistant, the outer layer is especially oil resistant, only need to be cleaned with water.

5. Anti-skid, the depth of the pavement structure increases the wear resistance of the ground, thus increasing the anti-skid performance, and the anti-skid value of the ground is higher than that of the ordinary pavement.

6. Fast and easy construction, easy to lay on the concrete pavement, easy to renovate the old pavement.

-02- Install node

At present, there are two construction methods for colored concrete pavement, that is, colored concrete embossed floor and colored concrete permeable floor.

1. Color concrete embossed floor

Embossing series (embossed floor) refers to the use of color fortifying agent, release powder and protective agent to decorate the surface of concrete while laying cast-in situ concrete, and the visual effect of natural stone, bluestone, granite and even wood is expressed by the color and convex texture of the surface of concrete.

Paper mold series refers to the selection of paper mold template pattern, arranged on the newly poured cement surface, spray color hardening agent to the area paved with template, and level, dry forming, pull off the template, clean the surface, and then on the protective agent, you can be a long time.

2. Color concrete permeable floor

Color concrete pervious floor refers to drainage concrete and ecological pervious concrete. Pervious floor is a new kind of porous light environmental protection ground paving material made by a certain proportion of small stones, 42.5 cement, and permeable admixture, water, color enhancer and stabilizer.

Pervious concrete is made of coarse aggregate surface wrapped with a layer of thin slurry bonded to each other into a honeycomb shape, which can let rainwater flow into the ground and effectively supplement groundwater; It is an excellent permeable floor material which can protect nature, maintain ecological balance and alleviate urban heat island effect.

Specific construction process and operation key points:

First, construction process

Compacting foundation → formwork setting → pouring concrete → surface leveling → spreading material → disk operation → mechanical operation → mechanical plate making → surface polishing operation → ground maintenance → shrinkage slit cutting

-03- Application case

Colored concrete can make the cement floor permanently show a variety of colors, patterns, texture, realistic simulation of natural materials and textures, so it is widely used in various aspects.

Colored concrete is suitable for decorative outdoor, indoor cement-based ground, wall, scenic spots and other materials, such as gardens, squares, hotels, office buildings, homes, sidewalks, driveways, parking lots, garages, building exterior walls, roofing and a variety of public places or old house decoration renovation projects.

1. The application of colored concrete in pavement

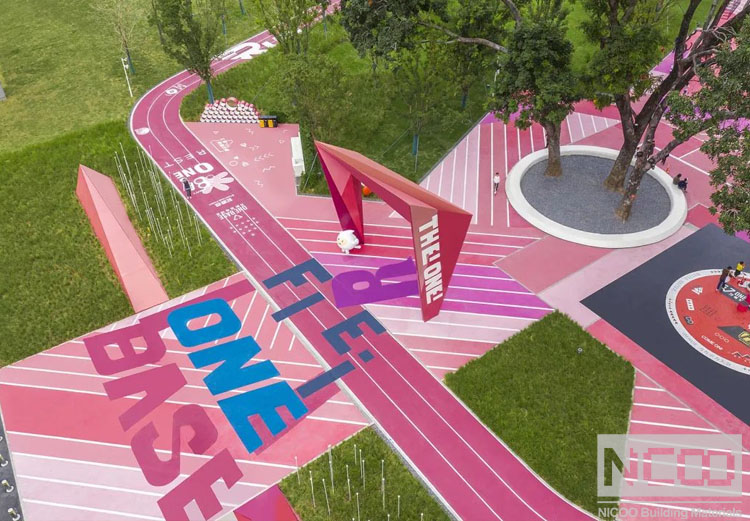

One Base Vanke Sports community

In order to radiate the appeal of youth and highlight the signature of vitality, pink and white colors are used to create a strong and rich sense of hierarchy.

2. Application of colored concrete in building facades

Yinchuan Great Wall YunDesert Winery in Ningxia, the design concept is inspired by the local landscape: the east side of the land is a grape garden, and the west side is surrounded by the Helan Mountains that divide Ningxia province and the Gobi Desert.

Artificial Traverstone Exterior Wall Case, Designers Look Over!!

Traverstone, a kind of natural stone, with its unique texture and beauty, shows a different charm on the exterior wall of the building.

How to Install Flexible Tiles

Flexible tile exterior wall brick with its unique texture and thin characteristics in the building materials market gradually popular, but many customers do not know how to paste? Today flexible tile manufacturers to give you a detailed explanation!

What is Rammed Earth Board?

First of all, correctly distinguish rammed earth board texture and rammed earth wall coating texture.

Dry Hanging Installation Of Fair-faced Concrete Slab On Exterior Wall

Precast concrete slab (precast cement slab) external wall dry hanging technology with its unique decorative effect and exquisite technology, gives new vitality to modern buildings. The technology uses dedicated connectors and pendants to mount concrete slabs directly onto exterior structures without the need for mortar or adhesives, creating a unique facade effect.