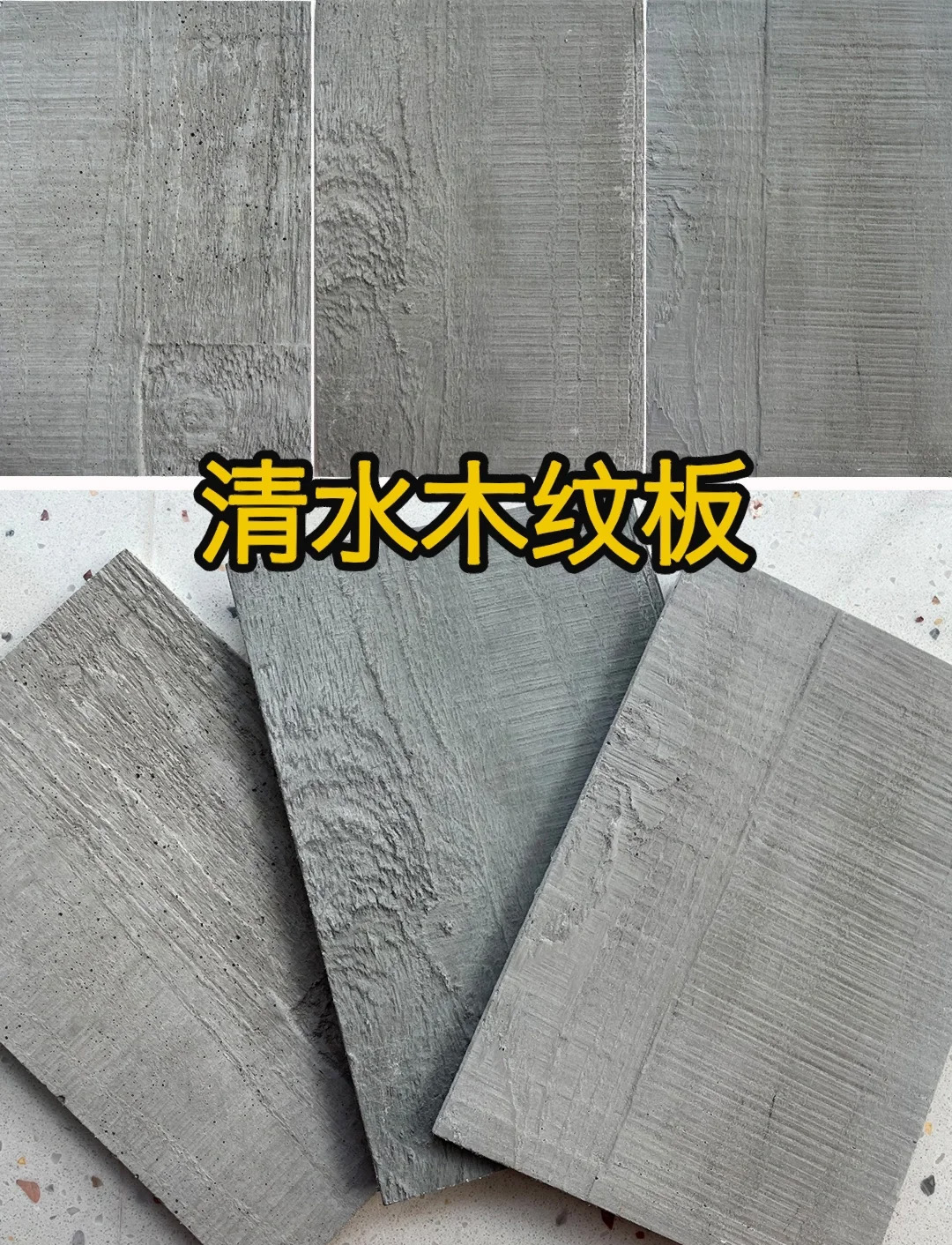

Designer Recommended Vintage Wood Grain Concrete Board

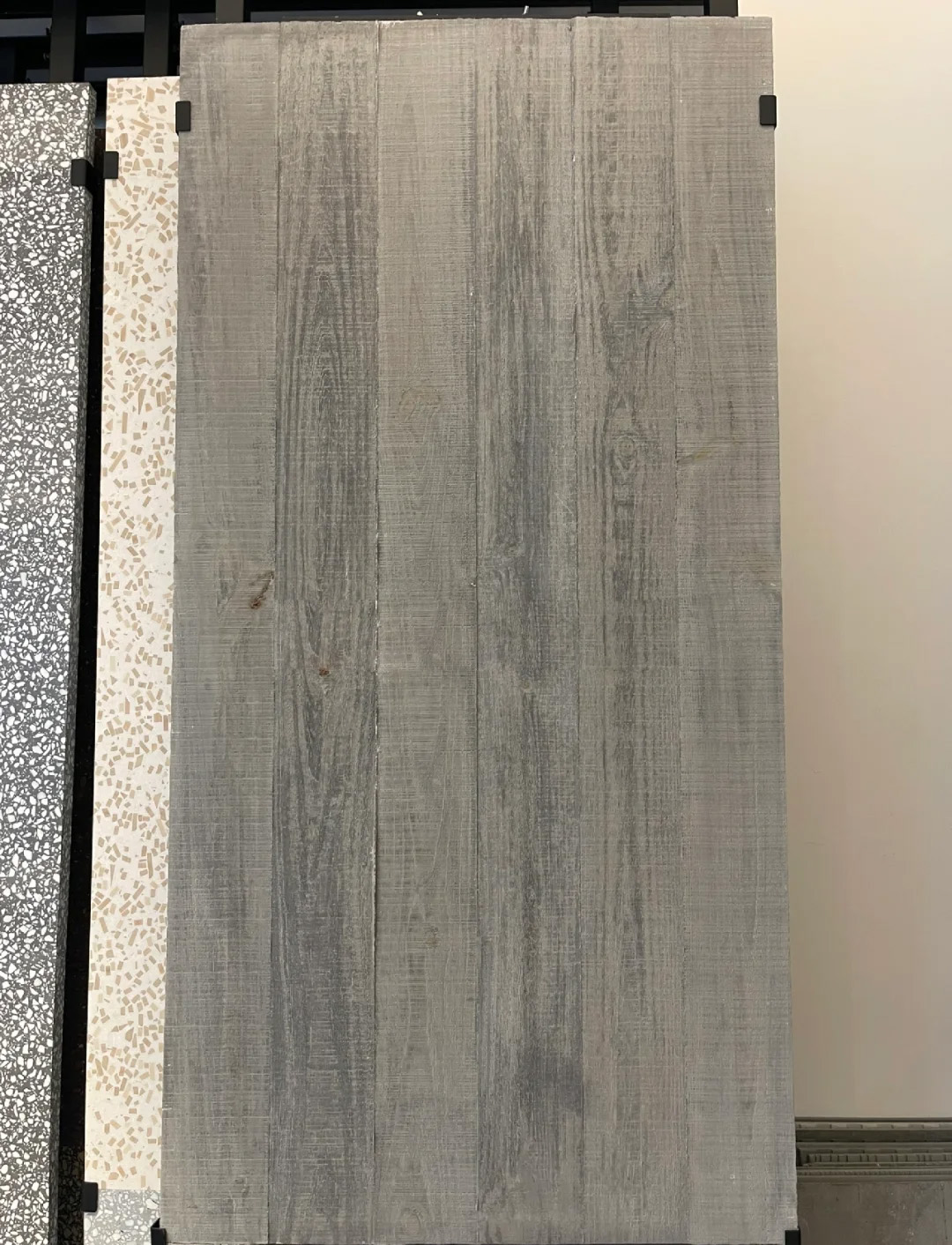

Specifications: 600mm x 1200mm X 10mm.

Concrete wood grain board is characterized by its surface with wood grain texture, thick texture with fine, can restore the real concrete industry style. This material is suitable for a variety of commercial locations, such as coffee shops, product showrooms, hotels and chain stores, and can be used indoors and outdoors.

Leading the way: Our concrete wood panels are the latest trend on the market, bringing a modern feel and unique industrial style to your space.

Unique design: Our concrete wood grain panels have a unique wood texture, thick texture with fine texture, to add a unique artistic atmosphere to your place. Diverse applications: Whether it is a coffee shop, product showroom, hotel or chain store, our wood grain board can be perfectly integrated into a variety of commercial places, creating an exclusive style.

High quality materials: We use high quality concrete materials to make wood grain panels to ensure durability and long service life for your investment.

Environmental choice: Our concrete wood grain board is an environmentally friendly material that is not only beautiful and practical, but also helps to protect the environment and build a good image for your business.

Fast construction: simple construction, conventional paving materials, no special process requirements.

Installation procedure refer to:

Prepare tools and materials: Ensure that the concrete wood grain board, tile glue, fasteners, and laying tools are ready.

Clean up the construction area: Before installation, ensure that the construction area is clean, level, and free of any impurities.

Apply tile glue: Evenly apply tile glue to the back of the concrete wood grain board, ensuring that the area applied matches the size of the board.

Lay the board: The board coated with tile glue is placed in the predetermined position, and then the buckle is used to level it to ensure that the board is closely fitted to the wall. About the gap: When installing, reserve about 1-3mm expansion joint between the plate and the plate to ensure that the overall effect meets the expectations.

Wait for drying: Waiting for the tile glue to dry completely, usually need to wait for a period of time, the specific time according to the glue instructions.

Cleaning and protection: After the glue is dry, clean up the excess glue and protect the already laid area to avoid damage during the drying process. Please note that the above steps are for reference only, and the specific operation depends on the actual situation and product description.

60 Questions about Concrete Projects - Part 4

The most comprehensive questions and answers about concrete are here. If you want to know more or want to buy decorative plate can contact Nicoo directly.

Absolutely useful, precast concrete exterior wall panel design

Learn about precast concrete wall panel design you don't know about.

How to Make Curved Cement Boards / Shaped Precast Wall Panels ?

In many decoration projects, we often see that there are some curved walls, columns, or corner positions that need to install plates, so we need some special curved or shaped plates to match. So how do we produce these curved slabs of cement?

Light-transmitting Cement and Concrete Interesting Texture Sharing

Nowadays, designers rarely find suitable textures when designing light-transmitting concrete. Today, I share some textures of light-transmitting cement for designers' reference.