Lightweight MCM Facing Flexible Ceramic Tiles Brick for Exterior Interior Wall

Lightweight MCM Facing Flexible Ceramic Tiles Brick for Exterior Interior Wall

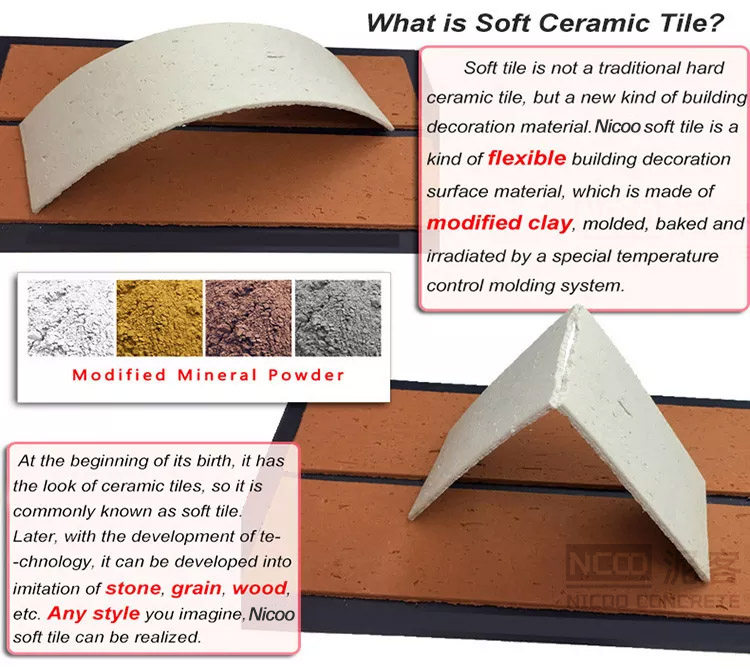

Why soft tile will be broken by force?

No matter which product , it has its own mechanical characteristics.

Such as : ceramic tile is hard , not afraid to fold , but very afraid of falling.

Soft tile is flexible , not afraid of falling , but afraid of folding.

Although it is flexible , it cann' t withstand large angle or repeated folding.

As wall decoration material , soft tile is not damaged by bending force on the wall . As long as the surface has enough impact resistance , the performance of bending does not affect its function .

You can do an experiment : Ceramic tile wall and soft tile ( flexible brick ) wall are hit with a hammer at the same time. It must be that the ceraic tile wall is broken , and the soft tile ( flexible brick ) wall is intact .

Technical Parameters

| Size | 230*58mm, 212*60mm, 240*60mm, 900*180mm, or customized |

| Thickness | 1.5-2mm |

| Weight | 3-8 kg / m2 |

| Water absorption | average 1.96% |

| Weather resistance | 100 freeze-thaw cycles |

| Dimensional stability | 0.25% |

| Flame retardant property | A2 |

| Air permeability | 0.95g/m2 h |

| Waterproof performance | at 0.3MPa pressure, keep 30min impermeable |

| Advantages | 1.Zero pollution,obtain from nature 2.Light weight,energy saving,easy teansprot,fast construction 3.Flexble & various,styles & vivid apperances 4.Reeze-thaw resistance,heat-resistance,anti-aging 5.Leavel a fire retardant effective flame retardant 6.Full body,anti UV,never fade 7.waterproof self-cleaning & siempre vivire product features 8.The color,tecture and size can be customization |

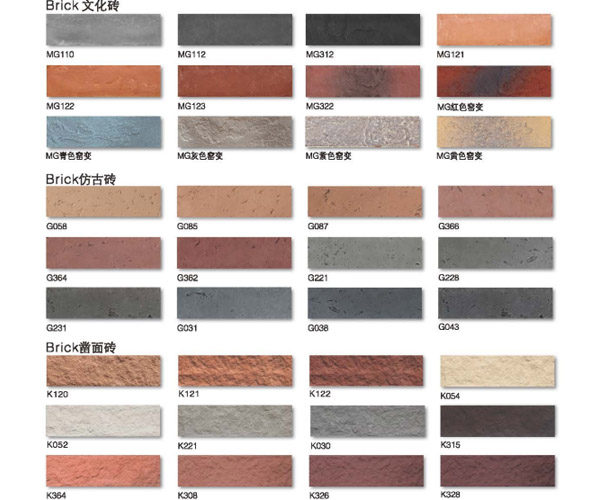

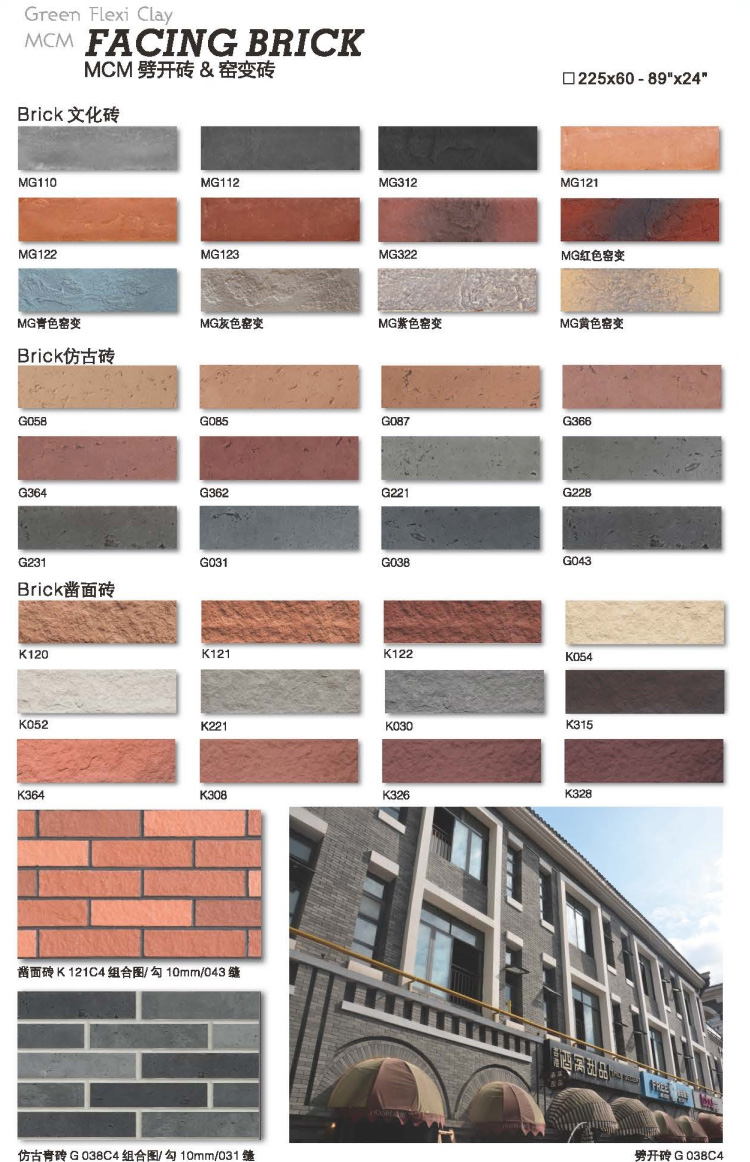

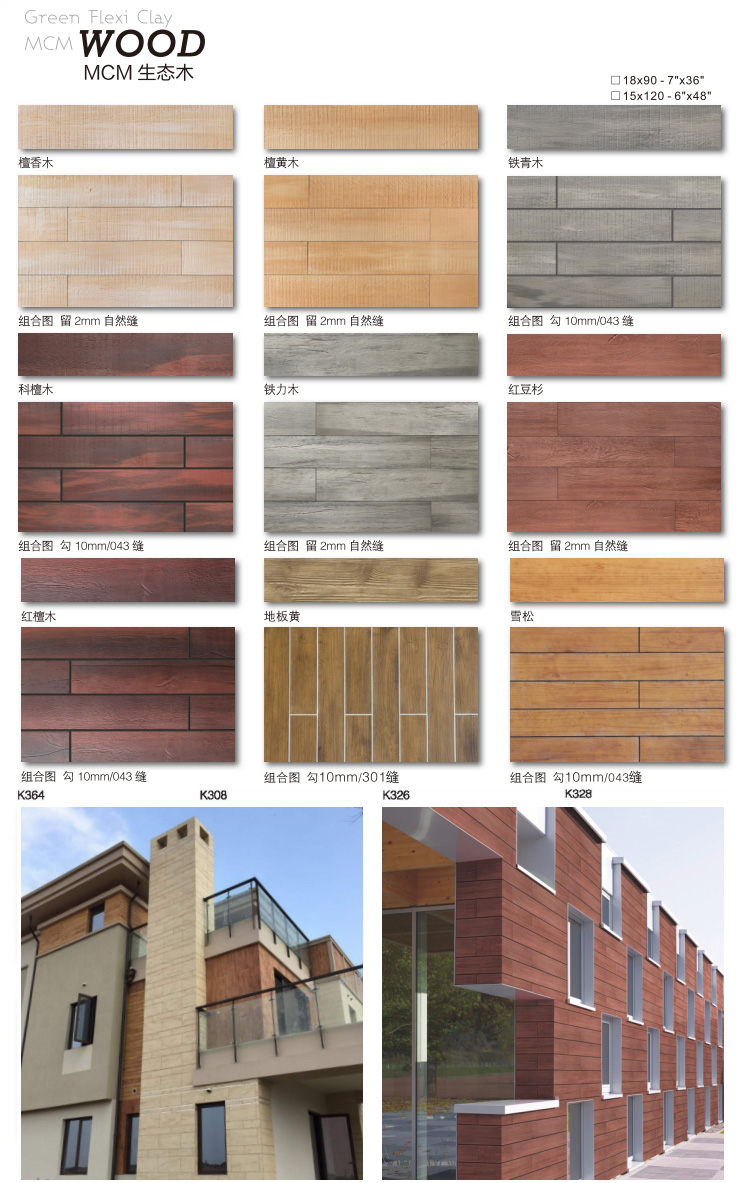

Product Series

ECOLOGCAL SPLIT FACING FLEXIBLE BRICK

●C-series facing brick 240X60mm

●Culture Brick

●Grid Paste Brick

●G-series Antique Brick 230X58mm

●K-series Devine Brick 225X60mm

●Large Size A-Series Facing Brick 600X115mm

●R-series Facing Brick 222X62mm

●Striped Wood Brick

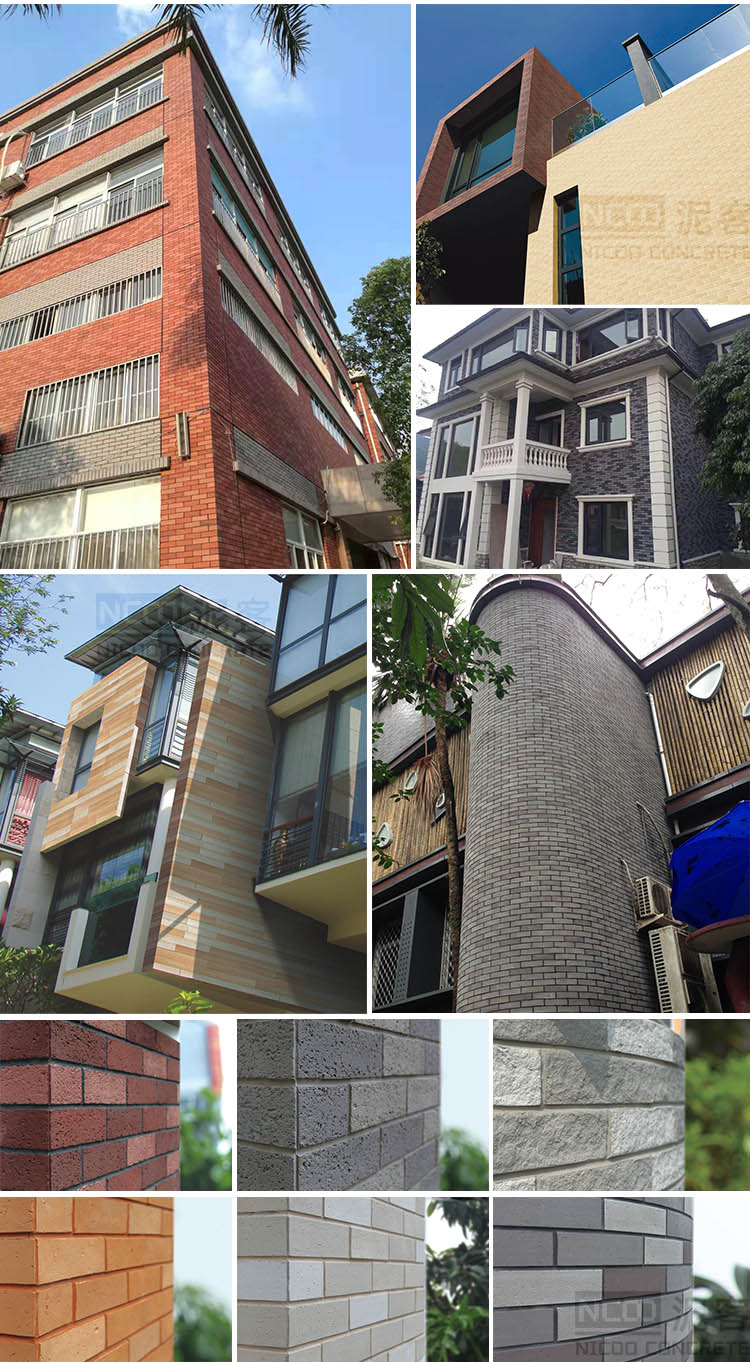

Case Show

Clearly visible texture. The jagged surface is like the mountain slide split by the edge tool held by the divine. General, disclosing the most primitive feature of the stone material, dirt resistant and self-cleaning , environment friendly and healthy.

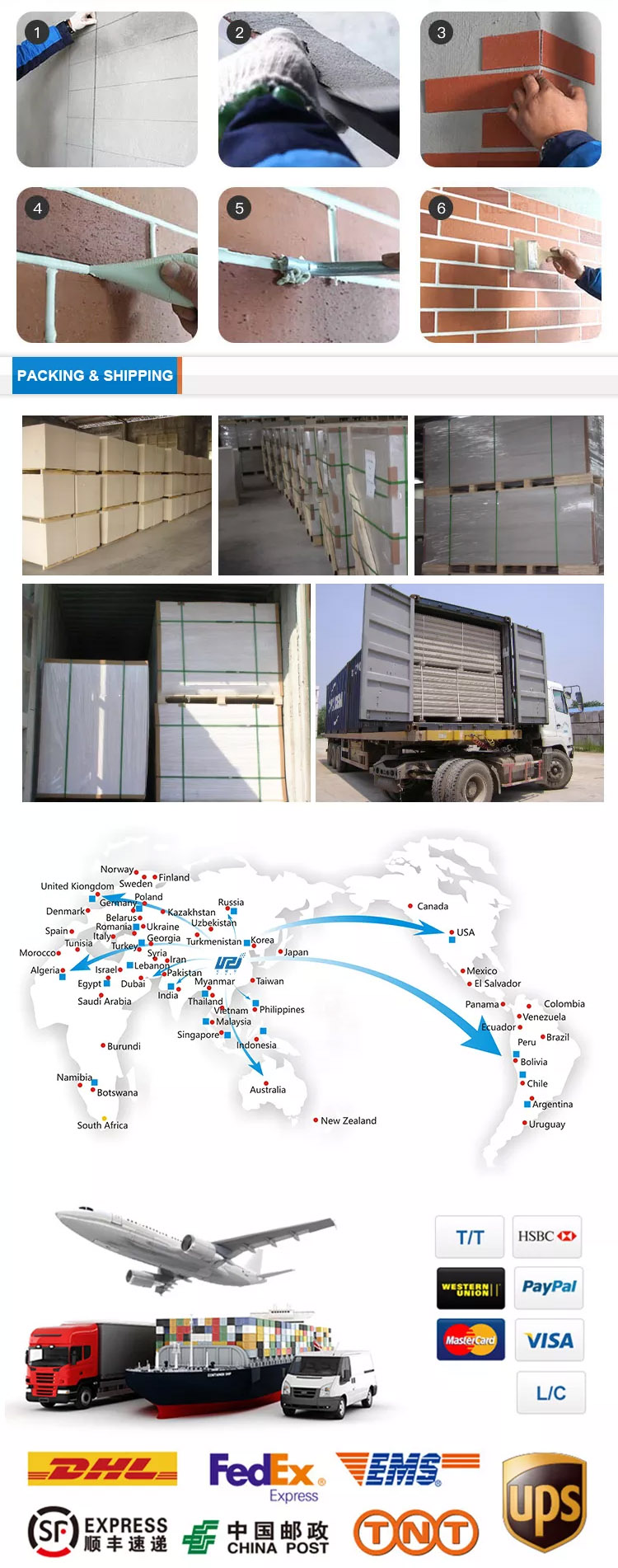

Installation

① After the base layer istreated with special interfacial agent, horizontal vertical positioning line.

② Use a spatula to make a two-component adhesive paste on the back of flexible brick tiles.

③ Stick the Angle first and then stick the big surface, press the soft flexible brick to adjust the width of the seam , and finally use the glue board to beat to make it bond evenly.

④ Put the two-component jointing agent into a triangular plastic bag, cut out a small opening in the plastic bag and then caulk.

⑤ After the caulking agent is half dry, use the bent steel head to pull out the concave hole. ( the steel head is 2mm wider than the hole )

⑥ Use a brush to remove the spilled jointing agent and wipe it clean with a half-wet sponge.

NOTE: If you have any questions about the installation, we can provide a detailed installation tutorial video, and you can contact us for more information.

FAQS

Q : What about quality control ?

A : We have perfect QC system for perfect products . A team with more than 5 experienced peoples who will detect the stone quality and specification piece by piece carefully Monitoring everyproduction process until packing is complete , to ensure product safety into container.

Q : How about samples ?

A : The sample are available for free , but the courier cost should be collect except for somelong-term parnters . So please inform us your couriers account , or prepay the cost through WestUnion , T / T , Paypal.

Q : How to ship cargos ?

A : We have some good shipping partner to help you take cargos from our Country to yourInland Port or Sea Port or Work-site or Warehouse.

Contrast of NICOO Fair-faced Concrete and Ordinary Concrete

As a common building material, concrete has a wide range of applications. In building structures, common concrete types include fair-faced concrete and ordinary concrete. This paper will compare these two types of concrete, explore their differences and application scenarios.

About Terrazzo

Professional manufacturer of terrazzo, artificial stone

How to Make Curved Cement Boards / Shaped Precast Wall Panels ?

In many decoration projects, we often see that there are some curved walls, columns, or corner positions that need to install plates, so we need some special curved or shaped plates to match. So how do we produce these curved slabs of cement?

What is the difference between fair faced concrete and ordinary hanging board

At present, it is difficult to distinguish the authenticity and variety of panels on the building materials market, so today we will talk about the difference between fair-faced concrete board and ordinary board.