Absolutely useful, precast concrete exterior wall panel design

Absolutely useful, precast concrete exterior wall panel design

01. Material summary

Precast concrete hanging board is an exterior wall decorative hanging board made of concrete as raw material, manufactured by factory precast, treated with high temperature and high pressure, and its surface treated with pre-coating technology. It realizes the realistic texture effect of fair-faced concrete and protects the weatherability of concrete for a long time.

02. Material properties

1) Surface texture

The surface has the texture of cast-in-place concrete through control in the production process

2) Good stability

According to the appraisal of the national testing authority, the bearing capacity of precast concrete hanging slab can fully meet the bearing standard of C20-C25 concrete.

3) High production efficiency

Through standardized design and industrial production, the mass production and high efficiency of fair-faced concrete hanging slab are realized, and the quality of fair-faced concrete construction project is improved and the construction period is shortened.

4) High stability

Fair-faced concrete slab can achieve a large slab width, visually giving people a sense of thick, and the effect is different from that of ordinary decorative sheet.

5) Durability

The durability and wear-resisting performance of precast concrete hanging slab is very superior, which is close to ordinary concrete.

03. Material technology

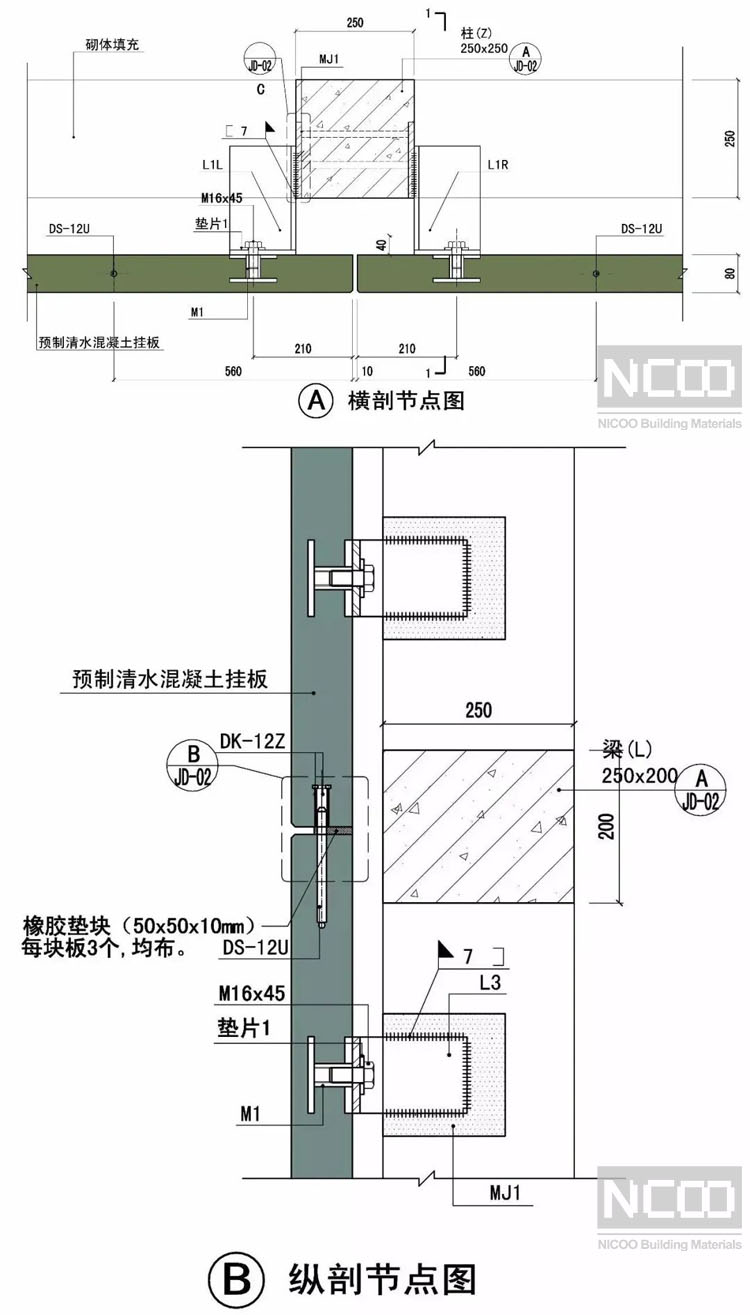

Precast concrete hanging slab construction process:

1, construction preparation -- 2, setting off positioning -- 3, check and deal with structural embedded parts -- 4, connector welding -- 5, external thermal insulation construction -- 6, hanging plate site transportation -- 7, hanging plate installation -- 8, anti-corrosion treatment -- 9, caulking construction -- 10, hanging plate protective agent coating

1. Preparation for construction

①. The main structure of the installation of the hanging plate (steel structure, reinforced concrete structure engineering, etc.) has been completed and passed acceptance.

②. The structural embedded parts for mounting the hanging plate have all been installed in place.

③ The side safety protection measures required for hanging plate installation have been in place.

④. Before installation and construction, the construction plan of hanging plate installation has been implemented, and the on-site installation operators have been trained and safety technology disclosed.

2. Locate cables

The surveyor shall release the positioning line of the structural embedded parts, the positioning line of the working face and the positioning line of each hanging plate (black ink) according to the unified structural axis and the reference elevation line provided by the construction drawings and the site, and organize the inspection line after the completion of the laying out

3. Check and dispose of structural embedded parts

Embedded parts in the construction of the main structure. According to the design requirements set firm, accurate position, in the structure of the embedded parts on the welding connector. To adjust the horizontal embedding deviation of structural embedded parts.

4. Weld the connectors

Weld the connector to the structural embedment according to the positioning line

5. External insulation construction

After the structural connectors are welded, heat preservation treatment should be carried out according to the design scheme, and concealed acceptance should be done in time. Insulation construction between hanging plate and structure shall be carried out according to design requirements and special insulation construction scheme.

6. On-site transportation of hanging plates

The site transportation of hanging plate is divided into horizontal transportation and vertical transportation. Horizontal transportation uses flat car, and vertical transportation uses tower crane, car crane or gantry frame for vertical transportation.

7. Mounting plate installation

①. After the hanging plate is hoisted to the installation position, the hanging plate is fine-tuned first, and the adjusting screw is used for coordination control to ensure the accuracy of the levelness and elevation of the hanging plate.

②. Then use the top wire to adjust the flatness and perpendicularity of the hanging plate, so that the hanging plate can meet the design requirements.

③ Finally, according to the level and the ruler to adjust the hanging plate to ensure that the seam width, level and verticality meet the design requirements.

④. After all the adjustments are completed, the connectors are preliminarily fixed, and the final fixation is carried out after the acceptance is qualified.

8. Anti-corrosion treatment

After the installation of the hanging plate, all weld positions must be treated with anti-corrosion, anti-corrosion measures can be applied in the form of anti-rust paint, and must meet the design requirements. The welding slag and other sundries on the surface of the weld should be cleaned before anti-corrosion coating.

9. Caulking construction

The selection of caulking sealant must be combined with the actual situation of the project and meet the design requirements to ensure that the building waterproof requirements. Before the formal construction must do sealant compatibility test, qualified rear can be used.

10. Brush the protective agent of hanging plate

If the design uses the face effect of fair-faced concrete, the surface of the hanging plate must be treated with the protective agent according to the design requirements. The protective agent brushing can be carried out before and after the installation of the plate.

04. Material price

Precast concrete hanging board price range is larger, mainly affected by the construction period and template more, general precast concrete hanging board offer in $30-100/㎡ above, different price surface decoration effect is different, the price is different.

Light-transmitting Cement and Concrete Interesting Texture Sharing

Nowadays, designers rarely find suitable textures when designing light-transmitting concrete. Today, I share some textures of light-transmitting cement for designers' reference.

Mosaic Terrazzo Application Advantages

Mosaic terrazzo is a kind of beautiful and practical material, which can be widely used in retail stores and various decoration projects.

Wide Application of Inorganic Terrazzo

The beauty of inorganic terrazzo floor is not only reflected in the ground.

MCM Tile Manufacturer Teach You To Identify The Quality

The MCM tile (soft tile) of various manufacturers will also have different differences, how to choose good quality flexible ceramic tiles is the key.