Exterior Wall Custom Prefabricated Fluted Beautiful Concrete Tiles

Exterior Wall Custom Prefabricated Fluted Beautiful Concrete Tiles

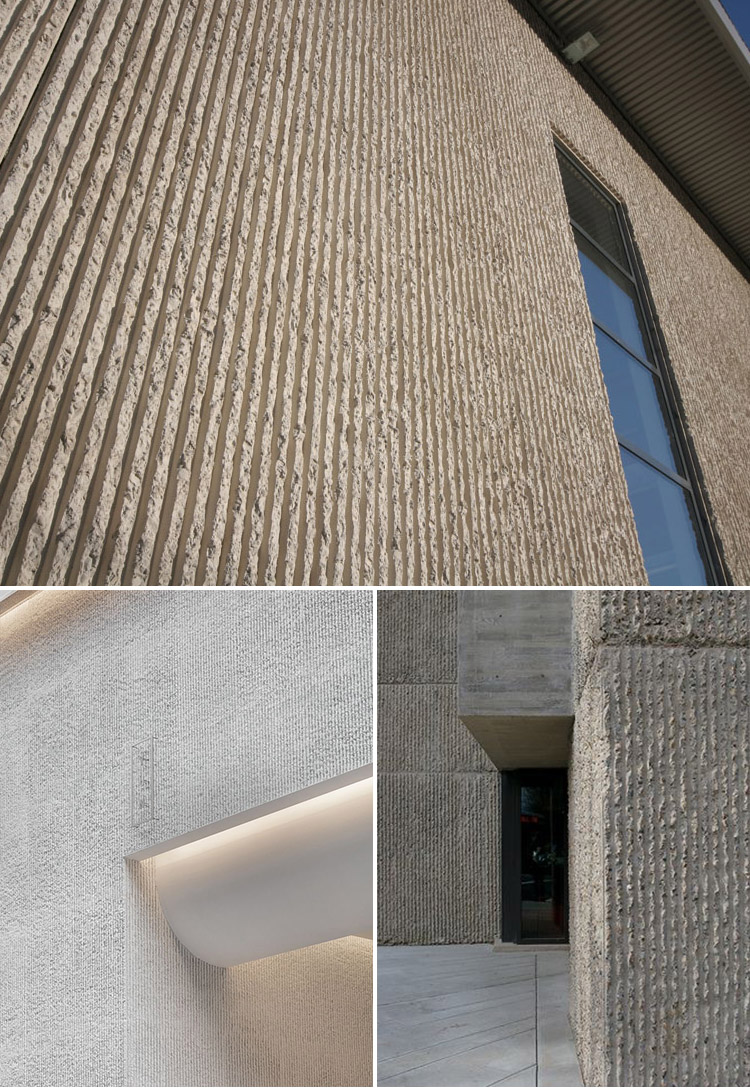

"Nicoo Fluted Concrete Tiles Board" is a kind of board whose texture is similar to that of cast-in-situ fair faced concrete buildings. As another process form of fair faced concrete, "Fluted Concrete Tiles Board" can more vividly show the finishing effect of fair faced concrete, and its surface plasticity is stronger, which is specifically reflected in the customization of its shape and surface three-dimensional texture. It is the multiple expression of this bump shape, three-dimensional and texture that makes wall rock marl board in indoor. External decoration is more widely used. It can effectively replace stone and other decorative boards. The "Fluted Concrete Tiles Board" has a variety of shapes, colors and three-dimensional effects. It can create different modern decorative effects through arbitrary molding of molds, so that the design can express its inner ideas at will.

1220 × 2440mm large specification is available, and the installation is particularly convenient and fast, which greatly shortens the construction cycle and saves the cost.

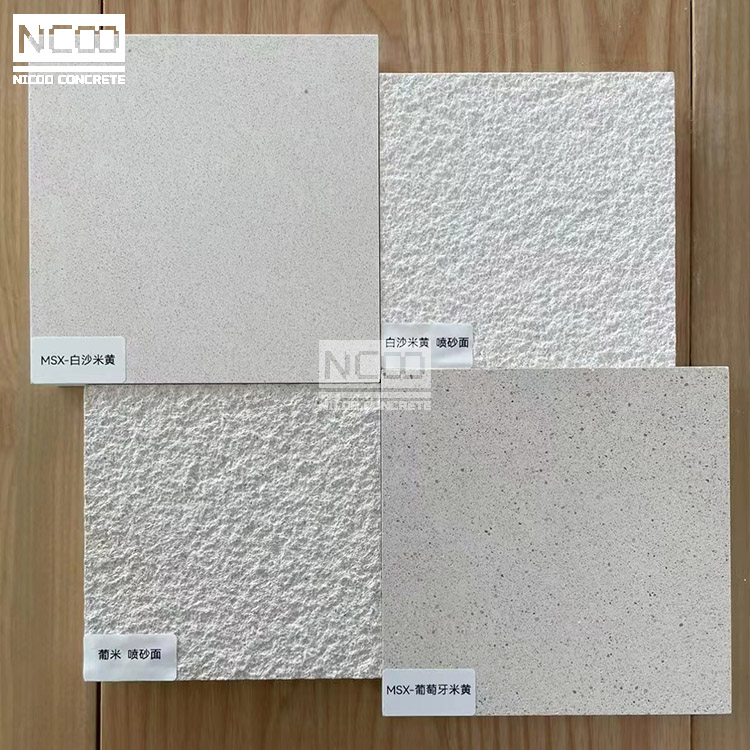

Product Display

Fluted Concrete Tiles Board can be matched with a variety of textures and sandstone mixes, we have concrete with different finishes, please contact us for more information on Fluted Concrete Tiles.

Product Cases

Our Fluted precast panel adds bold vertical lines that will create a striking visual element for any space. Using a variety of formliners to achieve the geometric depth, the Fluted panel is ideal for wall surfaces, both interior or exterior.

Product Installation

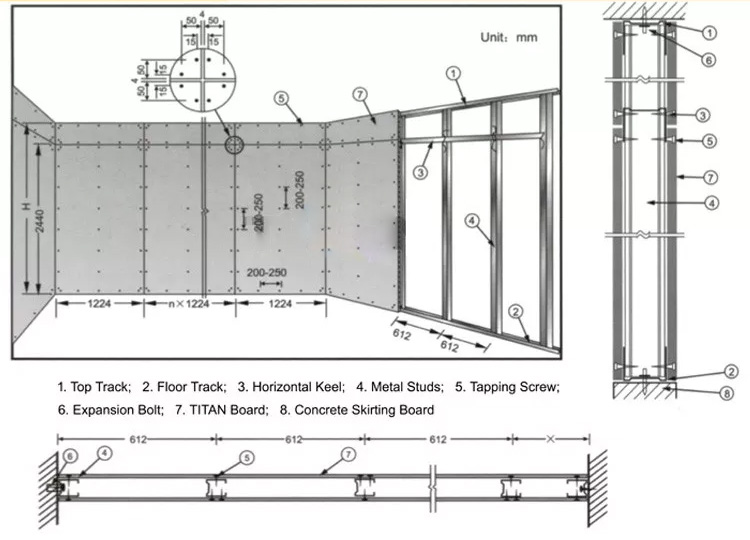

Partition Installing Method

1. Galvanized Metal Frame

A. The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

B. The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

2. Board Material Package Fixed

A. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

B. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

C. The expansion seam of about 4mm between boards should be kept.

D. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

E. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

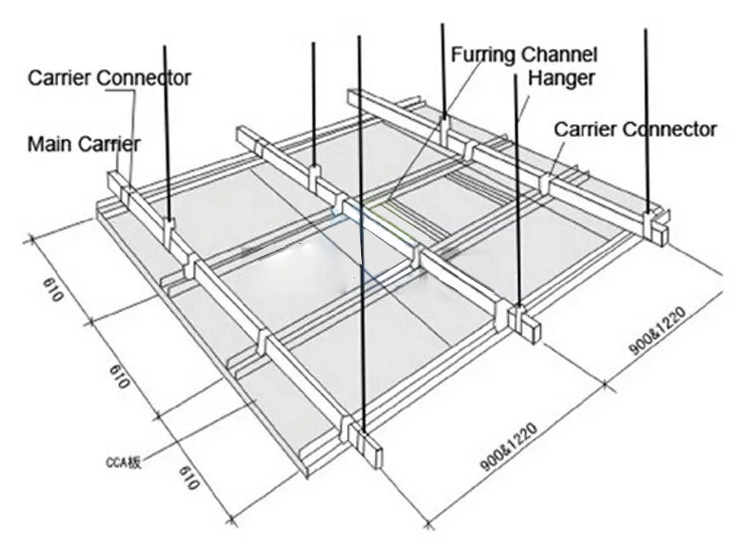

Ceiling Installing Method

1. Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.

2. Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3. Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4. Install the laterally supporting keel properly, its central ranges is 1224mm.

5. Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Our Services

Free samples can be provided as customer request,and if you are interests in our products, please feel free to contact us.

1. Payment: T/T

2 .Lead time: Samples: About 15 Working days;

3. Shipping freight are quoted under your requests.

4. Shipping port: Foshan, Guangzhou or Shenzhen port, Mainland China.

5. Discounts: discount based on the order quantity.

MCM Tile Manufacturer Teach You To Identify The Quality

The MCM tile (soft tile) of various manufacturers will also have different differences, how to choose good quality flexible ceramic tiles is the key.

High Grade Light Gray 800*800 Mosaic Terrazzo with Marble Particles Decoration Project

The natural white aggregate is neatly arranged on the floor, just like a cheese neatly arranged, so that every guest who enters the store is bright.

Unique Design 800*800 Potato Powder Large Particle Terrazzo

Puzzle style reinvention, custom design is a bit miscellaneous; Both have chosen to firmly take the customized route, this is today's production line master said the most warm words; Okay, so let's continue with the size effect... !

Why choose inorganic travertine?

New building material prefabricated inorganic traverteite plate.NICOO can provide free samples, so that customers more intuitive to see the quality of traverite plate.