Bamboo Molded Fair-faced Concrete Cladding

Bamboo Molded Fair-faced Concrete Cladding

01.

What is Bamboo Molded Fair-faced Concrete?

Product Features

Bamboo mold fair-faced concrete is a lightweight concrete wall panel with bamboo as a mold. It uses specially prepared concrete raw materials and aggregate.

It consists of the core of fibrous reinforced concrete and ultra -light composite materials. A layer of protective film is also sprayed on the surface to save maintenance costs.

In general, if small volumes of this type of concrete can be poured using native bamboo, in large quantities, or if fair-faced concrete is poured in some moulded areas, it is necessary to upgrade the bamboo formwork, mostly in the form of soft molds, to make the bamboo into a reusable mold, so that the whole of the bamboo formwork fair-faced concrete wall remains unified.

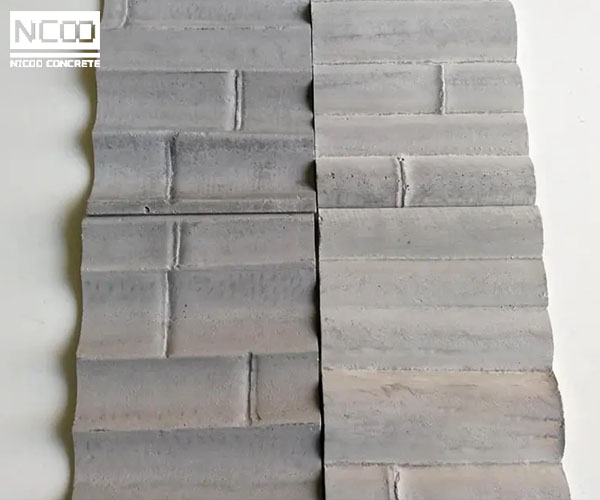

Product Specification

Under normal circumstances, the conventional thickness of the finished product is 2 to 28mm, and the thickness of different types of thickness and size can be customized by 600mmx1200mm, 800mmx3000mm, 3500 x 1200 mm.

Scope of Application

Inner and outer walls and custom furniture facade shape. The decorative boards are prefabricated by the factory, and the transportation can be installed directly to the scene.

02.

Bamboo Molded Fair-faced Concrete Advantages

● Wide -proof and waterproof construction, cheap cost and not fade.

● The application range is wide, the surface of the building, the interior wall, and the surface of custom furniture are available.

● Break the cold stereotype of concrete, the material is ecological and environmentally friendly, non -toxic and odor, and natural texture.

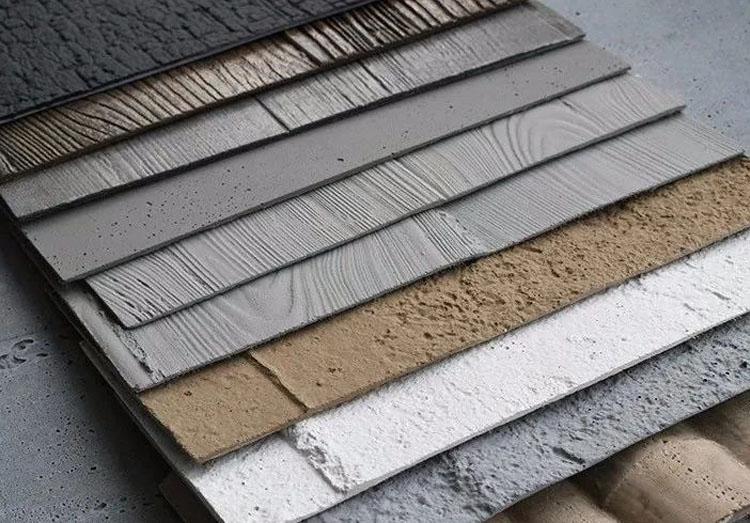

In addition to bamboo models, there are also series of wood models, stripes, rammed soil, etc., which meets the decorative requirements of various spaces and styles

03.

Bamboo molded concrete construction process

By nailing a certain specifications of bamboo pieces on the large template, the entire template system forms a stable and reliable support system through the internal and external steel tubing scaffolding. After the concrete pouring is completed, the model is formed in an orderly decorative effect.

Bamboo concrete board installation solution

Bamboo mold fair-faced concrete installation is convenient and quick, the best installation scheme is straight row nail installation and structural adhesive installation, the base is best for flat cement board or wood, the external wall of the building is recommended to take the form of dry hanging.

● Adhesive form

Process: Founding at the grassroots level → Fine woodworking board bottoming → Bamboo mold clear water concrete plate on the back of the back side of the plastic, structural glue (nail -free gum) is 5cm from the border of the board, dot -shaped, point spacing 10 ~ 15cm, paste → details → complete Essence

PS: The inner wall cannot be used as a grassroots, because the surface of the gypsum board has paper, which makes the paste not firm. At the time of construction, it is necessary to ensure that the glue surface of the base and the plate should be fixed fixedly without dust.

● Nail hanging form

Under the premise of wooden board foundation, you can directly nail with lines and fix the board directly on the surface of the wooden board. Pay attention to the spacing of the nail, within 10mm from the edge.

● Dry hanging form

The exterior wall dry hanging process is similar to the stone dry hanging process.

Note:

Pay attention to the seam of the plate surface. Because the pouring plate has a certain thermal expansion and contraction, the characteristics and elasticity of the wet and dry shrinkage, the inner wall is recommended to leave the process seam.

When the exterior wall is implemented, the gap between the pouring plate is filled with neutral sealing gels without silicone oil as much as possible.

04.

Applications

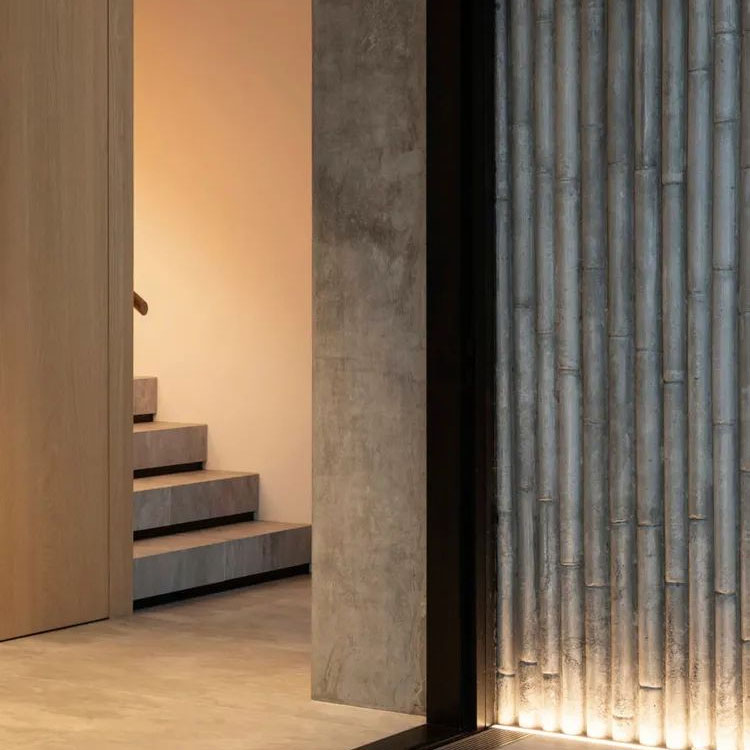

In the decoration of Homestay Hotel Decoration, the designer wants to bring guests a special experience different from the urban space. The courtyard wall is formed by casting bamboo mold concrete, hoping to fit the atmosphere of the surrounding natural mountain.

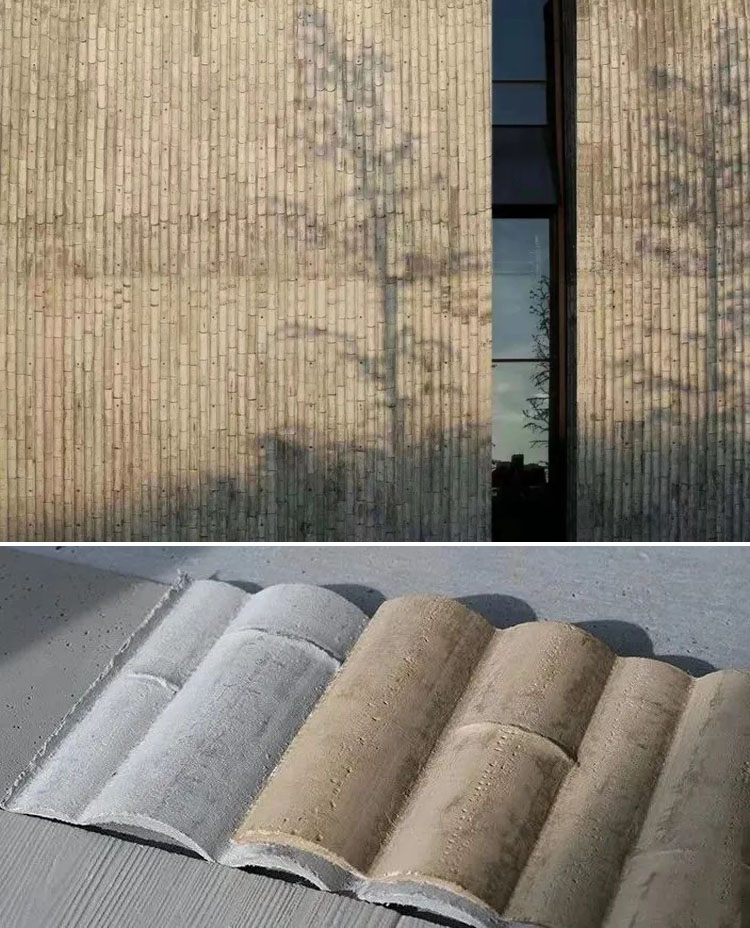

From the appearance, the effect of each kind of bamboo is a section of uneven surface as decoration, from a distance, the texture and texture of bamboo is fully expressed, bringing the architectural surface into a simple style; From the point of view of practical value, bamboo, and is a piece of bamboo assembly, its cracks, bamboo joints and other places of concrete are mostly rough, its decorative effect is also in a rough and original style decoration, in outdoor application, this rough finish, under the natural erosion, can absorb dust and dirt in its interior, Even if there is dirt on the surface, it is not obvious. Rough with delicate, delicate and wild, bamboo strip formwork fair-faced concrete, expressed is the original game and decorative beauty.

Each beach villa in the nursing home resort is covered with undulating green roofs and walls of bamboo texture, and has an endless sea view vision.

The facades are made of cast-in-place concrete and bamboo stencils, while locally sourced bricks are exposed as decorations on the inner walls. An airy cavity separates the concrete and brick walls to protect the interior space from the heat. The concave and convex surface of the bamboo-patterned fair-faced concrete acts as the material's insulation from heat, keeping the building warm even in the tropics.

The facade of the building uses the native bamboo of Nantou, Taiwan as the template. The wall of clear water bamboo mold with special bamboo slub texture is poured to strengthen the interpretation of light and shadow on the building.

Contact us for the latest catalogue and prices!!!

What is the difference between fair faced concrete and ordinary hanging board

At present, it is difficult to distinguish the authenticity and variety of panels on the building materials market, so today we will talk about the difference between fair-faced concrete board and ordinary board.

FAQS About Flexible Tiles

What's flexible tiles?

Unique Design 800*800 Potato Powder Large Particle Terrazzo

Puzzle style reinvention, custom design is a bit miscellaneous; Both have chosen to firmly take the customized route, this is today's production line master said the most warm words; Okay, so let's continue with the size effect... !

Dry Hanging Installation Of Fair-faced Concrete Slab On Exterior Wall

Precast concrete slab (precast cement slab) external wall dry hanging technology with its unique decorative effect and exquisite technology, gives new vitality to modern buildings. The technology uses dedicated connectors and pendants to mount concrete slabs directly onto exterior structures without the need for mortar or adhesives, creating a unique facade effect.