Designers must understand the difference between terrazzo and terrazzo tiles

Designers must understand the difference between terrazzo and terrazzo tiles

Terrazzo is divided into three types :

1. Cast-in-place terrazzo

2. Terrazzo prefabricated board

3. Terrazzo tiles

[Casted-in-place terrazzo]

Casted-in-place terrazzo is the crushed stone, glass, quartz stone and other mixed into cement to make concrete products on site after pouring, surface grinding and polishing.

It is the most beautiful and the most perfect choice, without any gap, strong unity. There are real particles, good texture, the most traditional approach. However, there are more large-area tooling, small home improvement area, cumbersome construction and high cost, and the sander is a disk, so there is a risk of uneven grinding edges and corners by hand. The cracking probability of floor heating is higher.

Advantages:

The particle is real, one body forming without gap, the whole sense is strong. You can design any pattern. Very beautiful

Disadvantages:

There is hot carbylamine cold shrinkage, easy to crack, easy to change color

⚠ Today's solution:

It can be inserted into the split copper strip to give the space of thermal expansion and cold contraction.

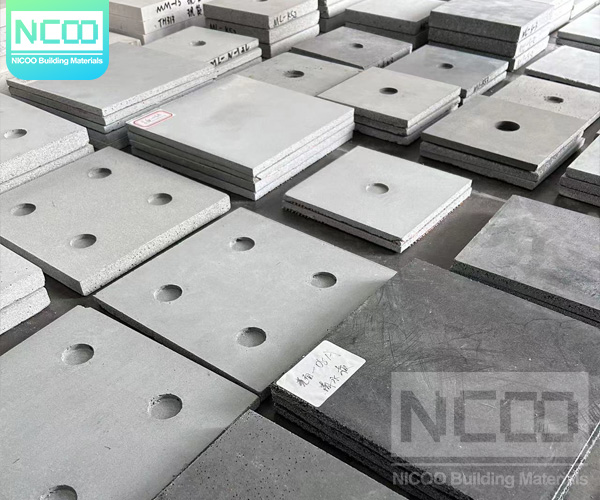

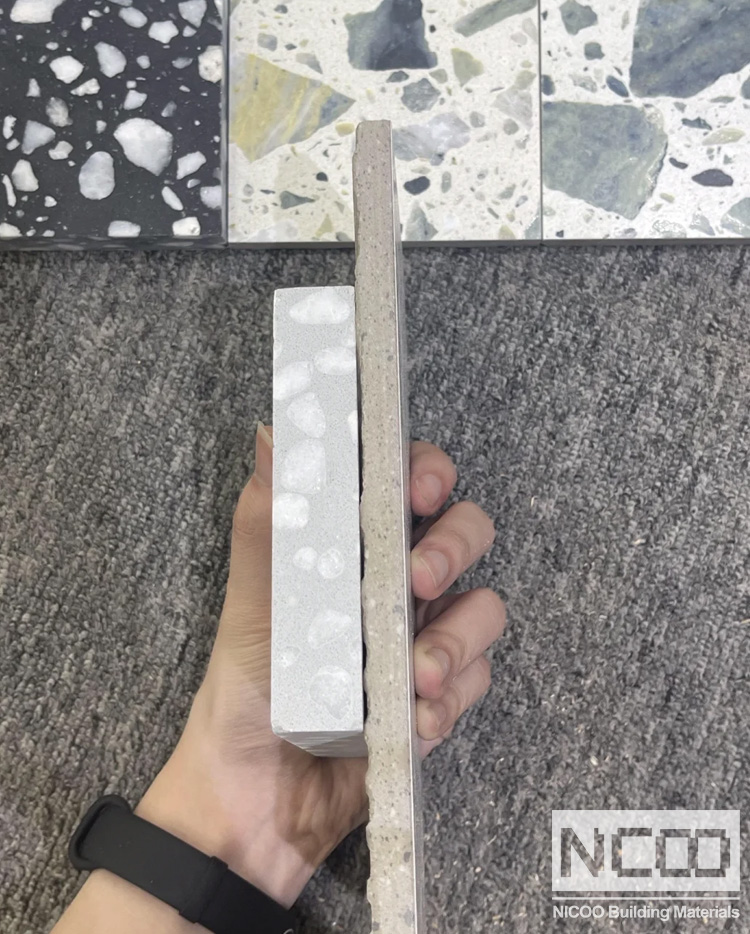

[Terrazzo prefabricated board]

The material is consistent with the castin, but it is cut in blocks, and it is directly laid like a floor tile. The size of the general household is 60* 60/80 *80/60*120, and the thickness is generally 1.5-2cm. It needs to be polished after laying.

Advantages:

Paving is more convenient than casting in situ, and is a good choice in the absence of a suitable construction party. The walls and floors can be paved, and they can be processed into sinks, desktops and everything you want.

Disadvantages:

How much paving will leave the seam, the integrity is not enough. It needs to be polished and polished, which is more than one process of tile pasting. There is an additional charge.

Prefabricated board will be more convenient than cast-in-place, like tile placement, but the prefabricated board can not do the same flatness as the tile, after the placement is completed, it also needs to increase the grinding step as the cast-in-place. As for the gap, you can do seamless grinding and sewing.

Seamless after far look no gap, look carefully or there will be splicing marks. Try to choose a color and texture similar to the material. The cost is the highest, the material itself is about USD 21-35/sqm, the polishing cost is USD 8/sqm , and the polishing cost is about USD 8/sqm. Seam price $2-4/meter. Prices may vary from region to region.

[Terrazzo tiles]

Terrazzo tile is to make terrazzo pattern tiles, do not believe the seller said that the whole body, there is no whole body of terrazzo tiles. The material inside the whole body should also have particles, similar to prefabricated board, ceramic tile can not do. The most convenient and easy to worry about, there is no risk of cracking and grinding, basically no need to take care of, and normal tiles are used. But the choice of color is small, the texture is not very good, and it will be more false at close range.

Advantages:

The most convenient, the same paving method as tile, easy to take care of later, basically no maintenance

Disadvantages:

The texture is not enough, just the printed particles on the surface

The above is the direction of analyzing the three options ~

Next, summarize the experience, friends who have a special love for terrazzo, follow us.

NICOO Decoration - Focus on inorganic artificial stone

The manufacturer of NICOO DECORATION specializes in prefabrication of various new environmentally friendly building materials and supports customization of various projects. Welcome to send your project to discuss together.

Application of Terrazzo and Selection of Aggregate

Inorganic terrazzo can have the same life as the building, seamless splicing of terrazzo, avoiding dirt, easy to operate, low cost, and satisfactory effect.

The Function of Concrete in Construction

Concrete is a building raw material, and its value is the largest in the construction industry. Because only it is the core material of construction. A building without concrete is like a living thing without flesh. Bones alone don't make an organism. Therefore, in the construction industry, the use of concrete is very extensive, it can be said that all people working in the construction industry will use a single concrete this substance, his role is self-evident.

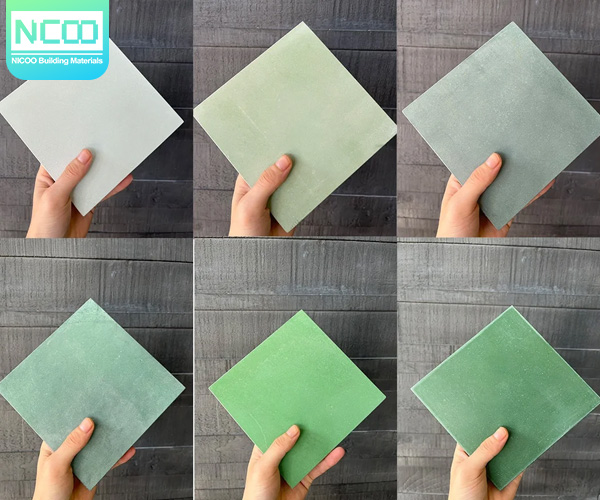

Hand-cast Fair-faced Concrete Slab Color Precast Cement Board

Who says fair-faced concrete slabs can only be drab gray? Today, I reveal to you a stunning treasure - colored concrete slab! It is not only a simple building material, but also a bright color in home design and garden landscape.