New Type Strongly Sticked Brick Thin Exterior Wall Facing Flexible Ceramic Tiles Cut Stone Slate

New Type Strongly Sticked Brick Thin Exterior Wall Facing Flexible Ceramic Tiles Cut Stone Slate

The raw material of flexible ceramic tiles cut stone slate is 90% soil and 10% water-soluble additive, which is sintered at high temperature above 400 ℃. Soft ceramic tile is to change the performance of the original soil, through the role of light irradiation, the production principle is similar to traditional ceramics.

Flexible tile technology subverts the traditional sintering process of hard ceramic tiles. The whole process is controlled automatically by computer. The "flexible" element is added to the deductive equation of ceramics. The clay molecules are modified and compounded. After firing at 400 ℃, the ordinary clay is forged into elastic and flexible tiles, which completely changes the hard, cold, heavy and fragile texture of ceramics. The longer the firing time is, the softer and more elastic the material is. After recycling, it can be reduced to powder and turned into soil.

| Performance Parameter | |

| Style | New Type Cut Stone Series |

Size | 600mmx300mm/1200x600mm or customized |

Material | Modified Clay Material |

Service life | About 50 years |

Thickness | 2.5mm-3.5mm |

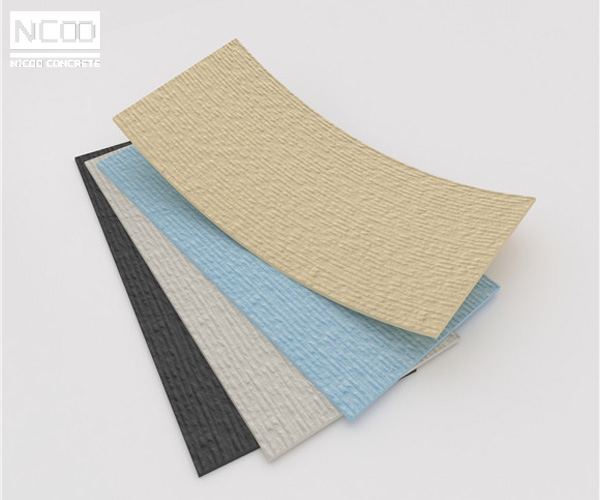

Color | Red, black, grey, white, yellow, beige, brown etc.,colors from natural soil. |

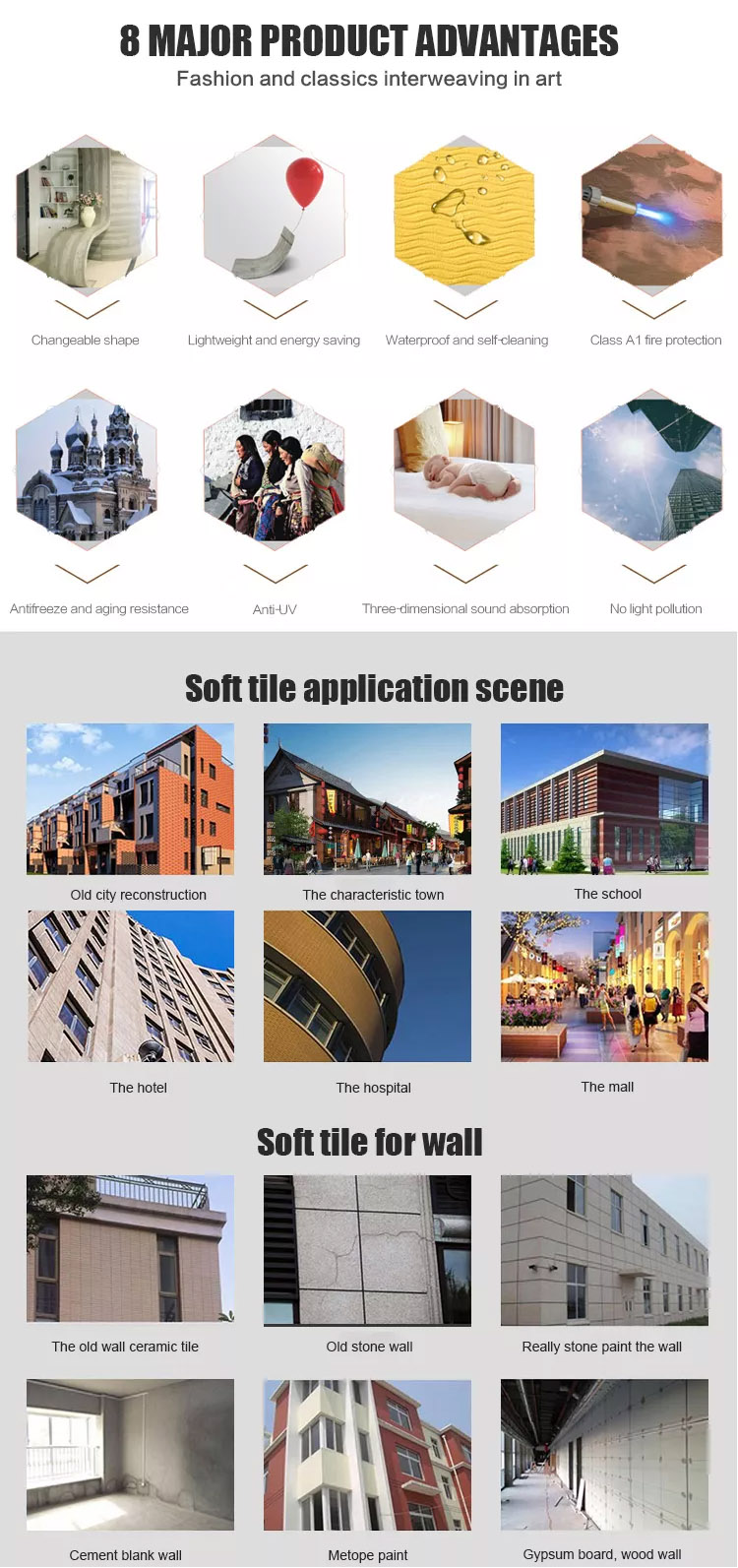

Advantages | It is thin and light, flexible and curvable, breathable, odorless & moisture resistant;Class A fireproof, Self-cleaning & Stain-Resistant, Anti-slip,Temperature & Moisture Control;Freeze-thaw Resistant,Durable,Water, Acid & Alkaline Resistant, Recyclable,Superb Expression. |

Energy-saving | Environment-friendly, Reduce 90% energy-wasting |

Application | Indoor/outdoor floor, wall, countertop, vanity top, stair and so on |

Safe | Light weight, thin, suitable for high-rises |

Packing | Standard Exporting Package |

Production Features | |

Flexible | It is made of Modified clay, which makes it elastic and flexible.It changes the hard,heavy and fragile feature of traditional tiles. |

Light&Thin | It can be made into 2-4mm thickness,3-6kg/sqm.Compared with hard tiles,flexible tiles can save cost of shipping and stock about 80%. |

Short production cycle | The production of flexible tile is one-step molding,about 7 days can finish production.Compared with the traditional hard ceramic tile,save about 70% time. |

Eco-friendly | From production to application,flexible tiles can save energy and reduce consumption 80%;since it can be recycled,it can be reduced to be powder,turned into clay. |

Temperature and humidity regulation | Flexible tile can make the surrounding temperature fluctuation tend to normal,and provide a stable and comfortable indoor environment by absorbing and releasing environmental heat. |

Simulation | One of the main characteristics of flexible tile is its rich appearance. The color of flexible tile can be provided by natural mud color or inorganic mineral pigment, and any color can be mixed according to needs. Its surface texture can be obtained by mold, and can be made into imitation natural stone grain, cut stone grain, wood grain, skin grain and so on. |

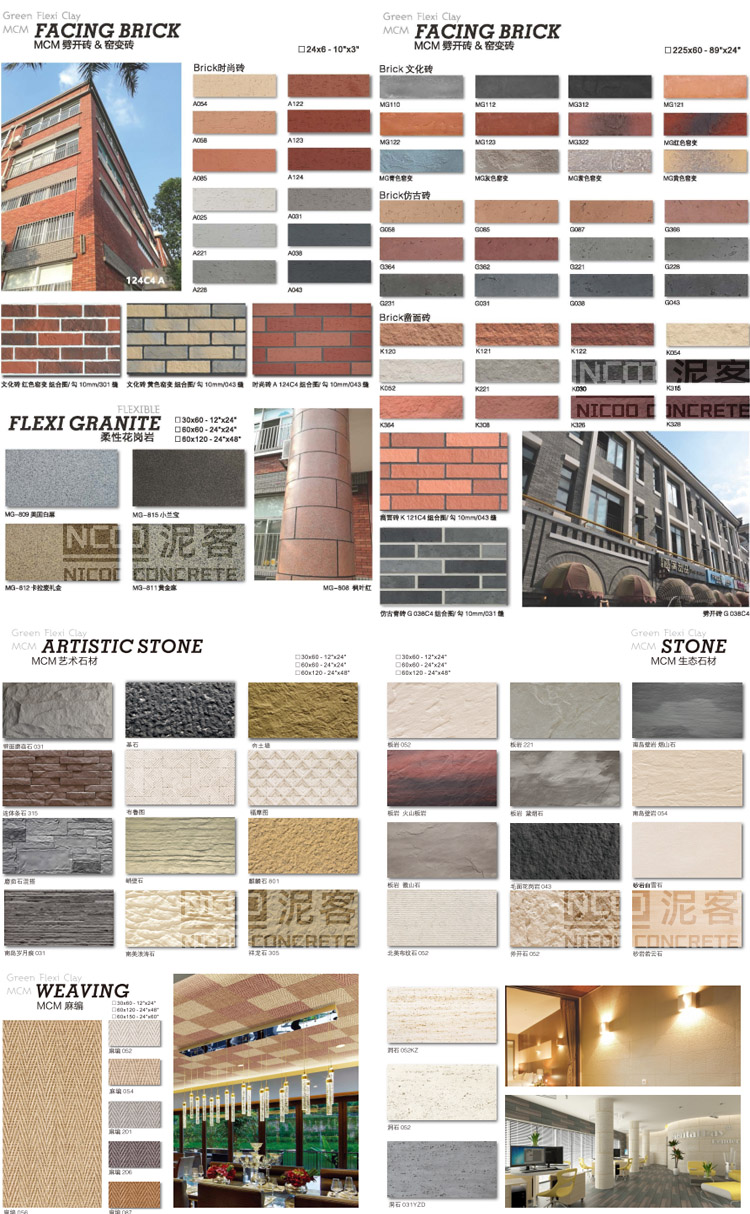

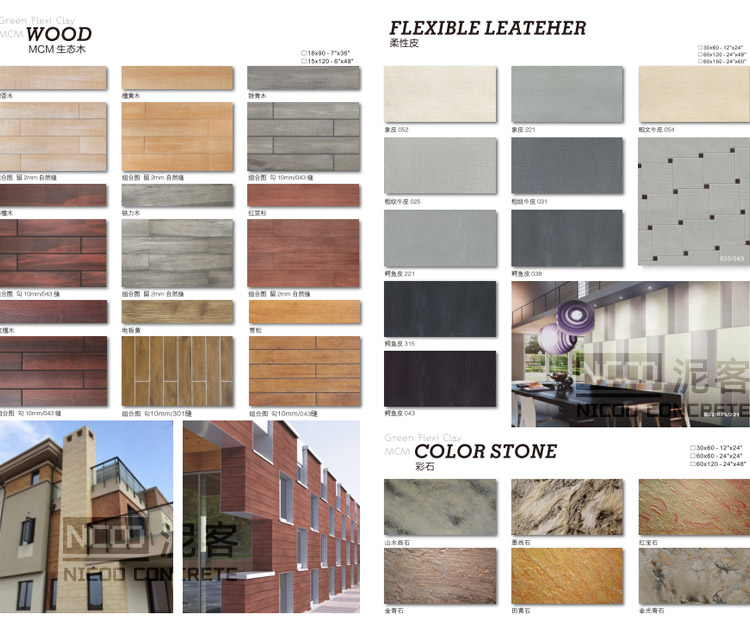

Product Series

It can be made various kinds of styles, likewise: wooden texture, brick texture, art-stone texture, leather surface texture, flexible stone texture, etc, about hundreds of style for choosing.

Foshan Nicoo Building Material Co., Ltd is a specialized in high-tech enterprise that is committed to covering green new material and it‘s related supporting production line of R&D, production, sales and international trade, viewing high-tech new material industry as pillar.

The Classic 60 Questions of Concrete - Part 1

Concrete classic 60 questions, worth collecting information!

The Three Indicators of Concrete Include

As a commonly used building material circulating in the construction industry today, it is common to hear about the three main indicators of concrete to meet design requirements. So, what are the three main indicators of concrete?

60 Questions about Concrete Projects - Part 4

The most comprehensive questions and answers about concrete are here. If you want to know more or want to buy decorative plate can contact Nicoo directly.

Application of Terrazzo and Selection of Aggregate

Inorganic terrazzo can have the same life as the building, seamless splicing of terrazzo, avoiding dirt, easy to operate, low cost, and satisfactory effect.