Art Series Fireproof Decorative Stone Grooved Striped Concrete Panels for Walls

Art Series Fireproof Decorative Stone Grooved Striped Concrete Panels for Walls

Product Description

The art series fireproof decorative stone grooved striped concrete panels is made of beach stone and concrete and is often used in traditional house decorative facades, courtyard decorative facades and outdoor gardens. Because it has a similar stone surface, it can also be used as a stone decorative wall, which can reduce the cost of stone and the weight of transportation.

Contrast can be eye-catching, decorative, and captivating to the viewer. In this case, dark rough concrete panels were used to contrast with strip corrugated siding. This helps break down the walls of the building, creating the illusion of 3D space and making the building layered in design.

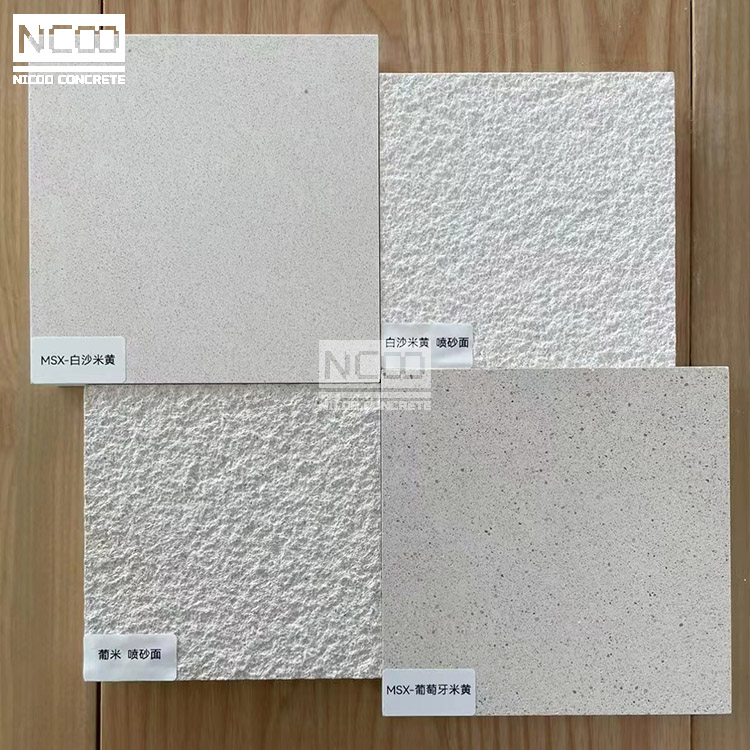

Product Display

Warm White Grooved Striped Concrete Board

Our Fluted precast panel adds bold vertical lines and stones that will create a striking visual element for any space. Using a variety of formliners to achieve the geometric depth, the Fluted panel is ideal for wall surfaces, both interior or exterior.

Grammercy Grooved Striped Concrete Board

As shown in the picture, the thickness of the sheet is 25mm, and the thickest part is 30mm. Since the 30mm sheet is used to make the thickness of 25mm, the corresponding cost and price will be a little higher. Any thickness and size can be customized, please contact us for more details and an accurate quote.

Advantages:

①. No dust emission,no dust generation,non-oxidation,mold prevention,insect prevention and moth prevention.

②. It is Acid and alkali resistance,chemical resistanceWear resistance,easy cleaning,low maintenance cost.

③. Class A1 fireproofing, neither toxic gas emission, nor black smoke in case of buming. It is the best choice of building boards.

④. Standardized production of the product precast cement board,site assembly and easy installation.

⑤. Our boards are with excellent bending strength,which is more than 13Mpa. High strength, durability and long service life.

Customization

All of our surfaces are made to order and available in a wide range of colours. Mixes can be designed to incorporate features such as quartz, granite, glass, shells and large aggregates. Since products are customized and individually molded, shapes can range from simple flat surfaces to complex grooves and forms. It can be mass-produced, making it a suitable product for commercial and residential development.

Installing Method:

1. Galvanized Metal Frame

a. The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b. The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

2. Board Material Package Fixed

a. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

c. The expansion seam of about 4mm between boards should be kept.

d. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

e. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

Please refer to the installation method of stone wall for details.

If you have any questions about the installation, please consult us.

What is Rammed Earth Board?

First of all, correctly distinguish rammed earth board texture and rammed earth wall coating texture.

Flexible Tile Manufacturer Take You To Understand The Price

We know that the price of flexible tile from each manufacturer is different, how do we know whether the price he gives is expensive or cheap, let's take a look.

Why choose inorganic travertine?

New building material prefabricated inorganic traverteite plate.NICOO can provide free samples, so that customers more intuitive to see the quality of traverite plate.

FAQS About Flexible Tiles

What's flexible tiles?