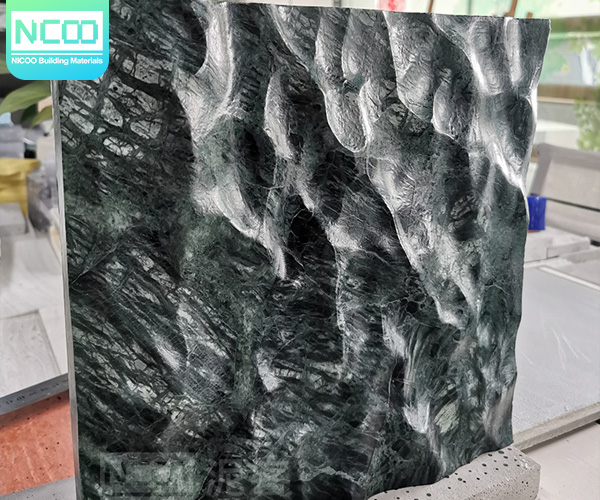

New Arrival 3D Green Liquid Natural Marble Panel Precast Marble Tile

Liquid marble is made of natural stone. Stone processing technology is diverse, with the development of science and the progress of technology, processed products have broken through our inherent imagination, marble as one of the hardest materials, widely popular in the building materials market, you may not imagine that one day, strong marble will become so soft and romantic.

Take the picture below for example

Yes, you read that right, this is the effect of marble made into a liquid surface, such a unique marble, is it the first time? Liquid marble is the hard natural stone through linear sawing, CNC engraving, hand polishing, thereby forming a visual liquefaction state.

Product specifications are customized according to the field size, including arc, round, etc., the thickness is 50mm.

Finish: Polished/matte

Fire rating: Class A

Common applications: art decoration, home products, wall floor, etc

"Features"

Linear sawing and CNC engraving can be combined to create a 3D effect of the stone, which can be carved on the stone surface with different depths and tilts of delicate realistic patterns, coupled with artificial fine grinding, will present the texture of natural form, highlighting the exquisite proportion under the light and shadow reflection, creating an artistic atmosphere

The liquid marble slab uses sophisticated 3D software to simulate the continuous waves of the sea being blown by the wind, and then uses mechanical sculptural contours and hand polishing to give the surface a vivid visual impression of sparkling light, allowing the viewer to walk between the rational design framework and the emotional visual effect.

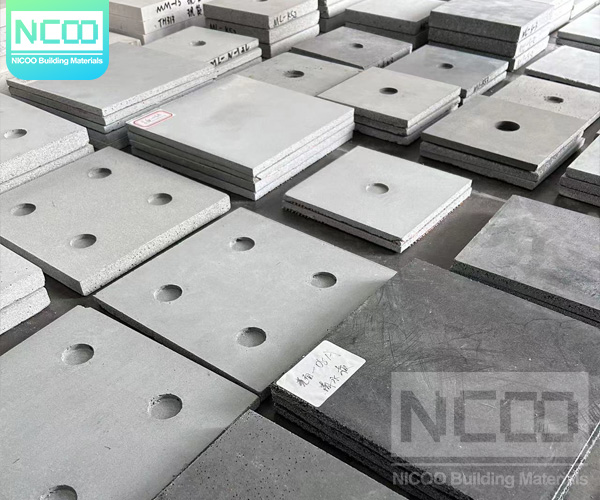

We can provide customized samples, the general size is 150*150mm or 200*200mm, the color is black, emerald green and dark green, because the liquid stone proofing is more complicated, the proofing time is generally about 10 days.

If you want a brighter effect, customers can also choose the waxing processing method.

Installation process

With the normal marble stone wall ground installation construction method (wet paste or dry hanging, according to the thickness of the decision, 50mm above the wall can be considered dry hanging)

Wet paste process: base leveling → plastering bonding layer (cement mortar) → stone paving → detail treatment → completion.

Dry hanging process: wall wiring → pre-row stone → play expansion bolts → Install steel skeleton, adjust → stone fixing → Glue protection → Finish

Construction note: The product is installed after the site, using the close-knit paving method, can be caulked or not caulked.

Ground construction: Liquid stone can choose a dense paving method, but it is also recommended to leave a gap of 2-3mm for paving.

Stone water ripple surface application is very good, can be used as background wall products, countertops, case several decorations; Placed in hotels, hotel lobbies, family living rooms, sprinkle white and bright water on the surface of water ripples to create an illusory waterscape world.

NICOO company's main products are: inorganic cement board, fair-faced concrete board, precast cement board, artificial stone, liquid marble, terrazzo, and other precast boards, and has exclusive research and development of fair-faced concrete board.Because of the focus so professional, we are committed to providing prefabricated plate solutions!

Contact us for more decorative stone quotes. leo@ltdisplays.com

The Function of Concrete in Construction

Concrete is a building raw material, and its value is the largest in the construction industry. Because only it is the core material of construction. A building without concrete is like a living thing without flesh. Bones alone don't make an organism. Therefore, in the construction industry, the use of concrete is very extensive, it can be said that all people working in the construction industry will use a single concrete this substance, his role is self-evident.

High Grade Light Gray 800*800 Mosaic Terrazzo with Marble Particles Decoration Project

The natural white aggregate is neatly arranged on the floor, just like a cheese neatly arranged, so that every guest who enters the store is bright.

Absolutely useful, precast concrete exterior wall panel design

Learn about precast concrete wall panel design you don't know about.

Unique and Creative Terrazzo Tiles Design

The floor that can achieve a large area of seamless is a new type of inorganic terrazzo material, using special materials and construction technology, the pressure on the floor is lighter, and the overall effect can achieve a seamless effect.